In today’s fast-paced industrial world, uninterrupted power is more than a convenience—it is a necessity. Manufacturing ...

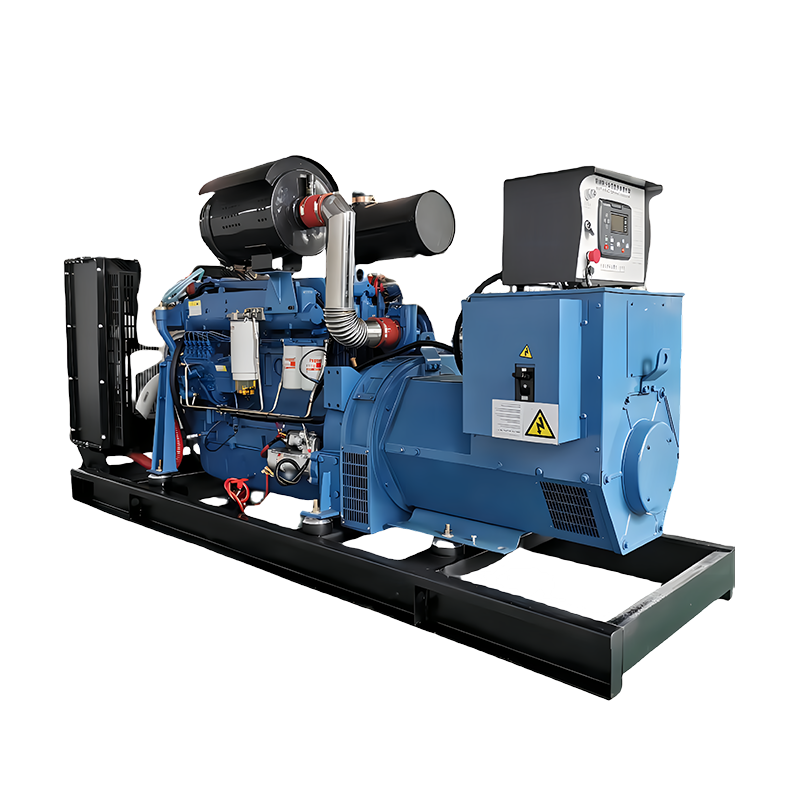

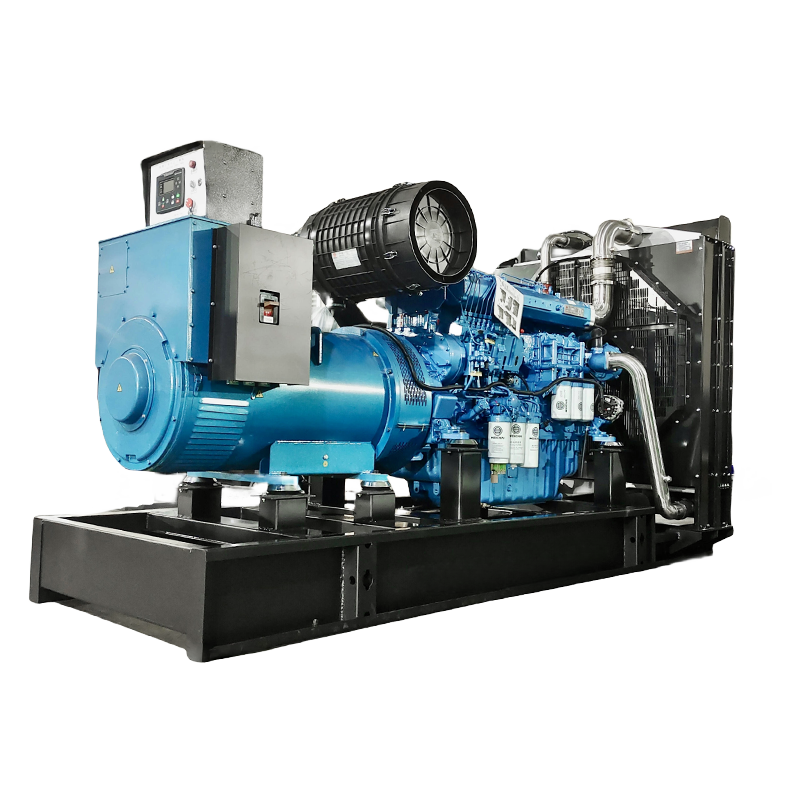

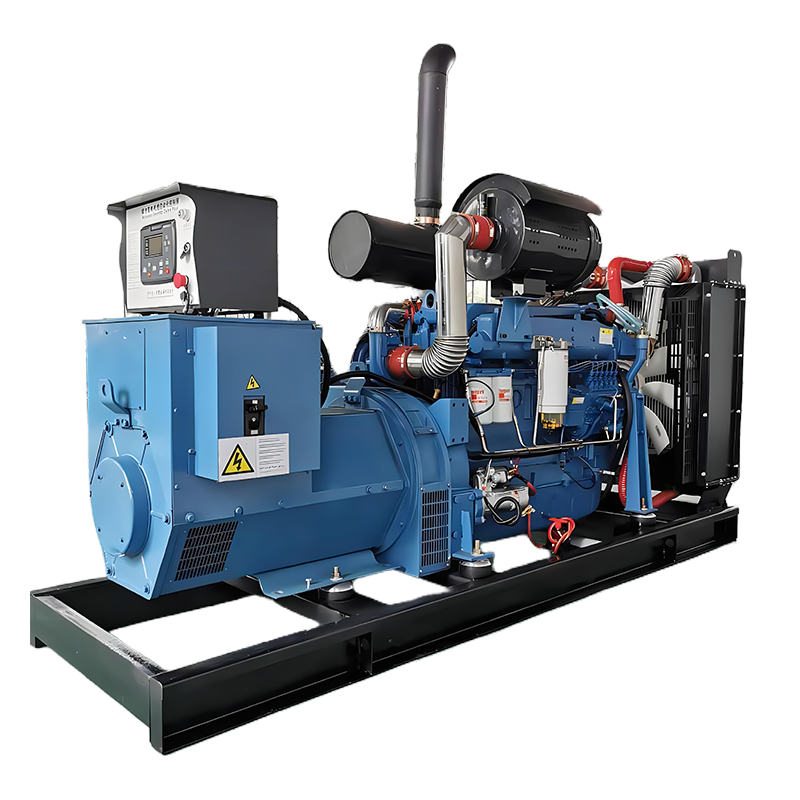

READ MOREWeichai generator sets are widely used in ships, national defense, communications, petroleum, medical treatment, mining, field rescue, agriculture and animal husbandry, and backup power supplies, etc. They use engines independently developed and produced by Weichai Group and are equipped with well-known brand generators. Weichai generator sets are widely used in ships, national defense, communications, petroleum, medical treatment, mining, field rescue, agriculture and animal husbandry, and backup power supplies, etc. The unit has excellent performance, advanced technology, reliable operation, convenient maintenance, high voltage regulation accuracy, good dynamic performance, compact structure, long service life, fast start-up, and can quickly reach full power in just a few seconds. In an emergency, it can reach full load within 1 minute (normal 5~30MIN). The shutdown process is short and can be started and stopped frequently. The power coverage range is 10kva-4500kva

You can choose the brand you want

You can choose the type you want

+86-18652407919

+86-0514-86593686

+86-18944498005

-

1

Support

Customization -

2

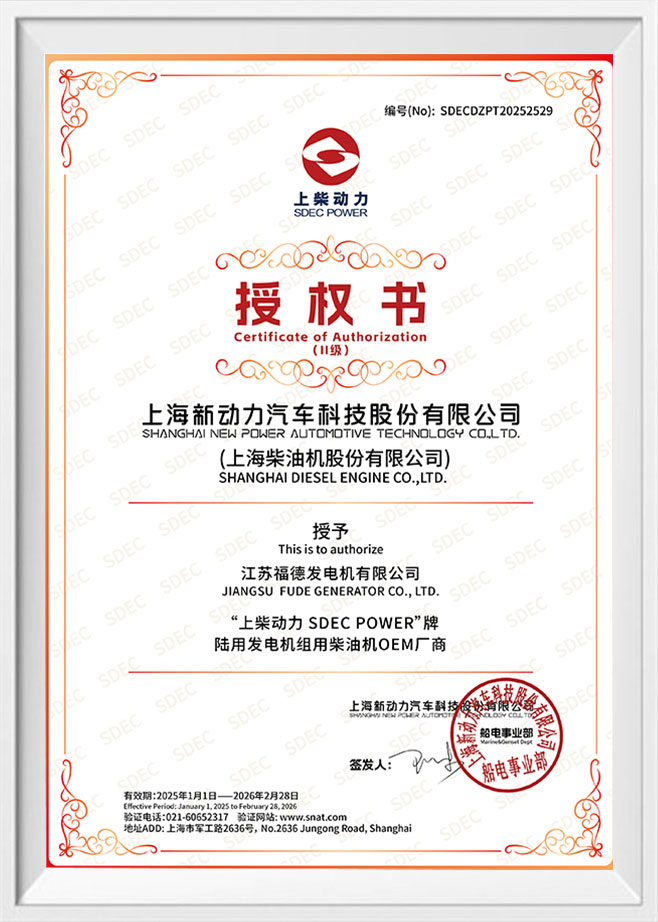

Own Factory,

Greatly Reducing

Costs -

3

Strict Quality

Control -

4

Strict Quality

Control -

5

Strong

Production Capacity -

6

More Considerate

Service

Request Quote

Request Quote

WEICHAI

| Diesel engine | The whole series adopts the Weichai engine as the power, with a power range of 10kVA-4000kVA. After years of product development and development of power devices, it has continuously absorbed fruitful results, modern science and technology, internal combustion engines, with advanced technical and economic indicators, compact structure, easy operation, easy maintenance, better performance, better service, and safer quality among similar products. | |

| Dynamo | Full range of options: Stamford/Marathon/Engga/Faraday and other brand generators; excellent excitation characteristics, so that the unit can withstand high power instantaneous loading with small voltage fluctuations and rapid recovery | |

| Control System | The whole series adopts the SmartGen HGM6110 control system, which integrates digitalization, intelligence, and network technology. It is used for the automation and monitoring system of a single diesel generator set, realizing functions such as generator set mains monitoring, automatic start/stop, data measurement, alarm protection, etc.; brands such as Shenhai and Comai are available. | |

| Cooling System | Standard configuration of 50℃ ambient temperature online radiator and closed water circulation cooling system can ensure rated power output ina harsh high temperature environment and provide support for long-term stable operation of the unit. | |

| Steel structure base | The built-in composite shock-absorbing system has excellent shock-absorbing performance. There is no need to install shock-absorbing pads to connect and fix the base foundation. The base is reasonably designed with reserved holes for forklifts and cranes. Installation and transportation are quick and convenient. The base is equipped with a split fuel tank as standard, which is convenient for later use and maintenance. | |

Request Quote

Request Quote

Random accessories and optional items

| Supplied accessories | Circuit breaker, battery, and connection, muffler, bellows, exhaust elbow, shock absorber, oil level gauge, instruction manual | |

| Optional items | Rainproof/Silent/Mobile | Oil-water separator |

| Heat exchanger--water tower cooling system | Fuel tank capacity customization | |

Request Quote

Request Quote

Generator set performance parameters

| Basic parameters | Frequency drop ≤3% | Voltage modulation ≤ 0.3% |

| Steady state frequency band ≤0.5% | Steady-state voltage deviation ≤±1% | |

| Transient frequency deviation ≤+10% ≤-7% | Transient voltage deviation ≤+20% ≤-15% | |

| Frequency recovery time ≤ 3S | Voltage recovery time ≤1S (voltage ±3%) |

Request Quote

Request Quote

Standard monitoring functions

| Monitoring Project | Three-phase voltage Ua, Ub, Uc | Three-phase current La, Lb, Lc |

| Frequency F1 | Active Power PA | |

| Apparent power PR | Power Factor PF | |

| Cooling water temperature WT | ℃Simultaneous display | |

| Oil pressure OP | kPa/Psi/Bar simultaneous display | |

| Speed RP Unit: RPM | Battery voltage VB Unit: V | |

| Timer HC can accumulate 999999 hours | The maximum cumulative number of startups is 999999 times |

Request Quote

Request Quote

Generator Set

| Unit Model | Prime Power(KVA) |

| FD-WC20 | 20 |

| FD-WC25 | 25 |

| FD-WC30 | 30 |

| FD-WC38 | 38 |

| FD-WC45 | 45 |

| FD-WC50 | 50 |

| FD-WC60 | 60 |

| FD-WC100 | 100 |

| FD-WC120 | 120 |

| FD-WC125 | 125 |

| FD-WC150 | 150 |

| FD-WC185 | 185 |

| FD-WC200 | 200 |

| FD-WC260 | 260 |

| FD-WC285 | 285 |

| FD-WC300 | 300 |

| FD-WC350 | 350 |

| FD-WC375 | 375 |

| FD-WC450 | 450 |

| FD-WC500 | 500 |

| FD-WC550 | 550 |

| FD-WC600 | 600 |

| FD-WC650 | 650 |

| FD-WC725 | 725 |

| FD-WC800 | 800 |

| FD-WC875 | 875 |

| FD-WC900 | 900 |

| FD-WC975 | 975 |

| FD-WC1100 | 1100 |

| FD-WC1200 | 1200 |

| FD-WC1250 | 1250 |

| FD-WC1300 | 1300 |

| FD-WC1500 | 1500 |

| FD-WC1550 | 1550 |

| FD-WC1680 | 1680 |

| FD-WC1800 | 1800 |

| FD-WC1975 | 1975 |

| FD-WC2000 | 2000 |

| FD-WC2185 | 2185 |

| FD-WC2450 | 2450 |

| FD-WC2700 | 2700 |

| FD-WC2750 | 2750 |

| FD-WC2875 | 2875 |

| FD-WC3300 | 3300 |

| FD-WC3500 | 3500 |

Request Quote

Request Quote

Diesel engine

| Model | Rated power/speed (KW/rpm) |

Maximum power/speed (KW/rpm) |

| WP3.2D20E310 | 18 | 20 |

| WP2.3D25E200 | 23 | 25 |

| WP2.3D33E200 | 30 | 33 |

| WP3.2D36E310 | 33 | 36 |

| WP3.2D44E310 | 36.8 | 44 |

| WP2.3D48E200 | 44 | 48 |

| WP4.1D66E200 | 60 | 66 |

| WP4.1D100E200 | 90 | 100 |

| WP4.6ND120E310 | 110 | 120 |

| WP6D132E200 | 120 | 132 |

| WP6D152E200 | 138 | 152 |

| WP7D185E310 | 168 | 185 |

| WP10D200E200 | 182 | 200 |

| WP10D264E200 | 240 | 264 |

| WP10D288E350 | 262 | 288 |

| WP10D320E200 | 291 | 320 |

| WP12D353E200 | 288 | 353 |

| WP13D385E200 | 350 | 385 |

| WP13D440E310 | 392 | 440 |

| WP13D490E310 | 450 | 490 |

| 6M33D572E200 | 520 | 572 |

| 6M33D633E200 | 575 | 633 |

| 6M33D670E200 | 610 | 670 |

| 6M33D725E310 | 675 | 725 |

| 8M33D800E200 | 730 | 800 |

| 8M33D890E200 | 815 | 890 |

| 12M26D902E200 | 820 | 902 |

| 8M33D975E310 | 890 | 975 |

| 12M33D1108E200 | 1007 | 1108 |

| 12M33D1210E200 | 1100 | 1210 |

| 12M33D1240E310 | 1130 | 1240 |

| 12M33D1320E200 | 1200 | 1320 |

| 12M33D1500E310 | 1350 | 1500 |

| 16M33D1580E310 | 1430 | 1580 |

| 16M33D1680E310 | 1530 | 1680 |

| 16M33D1800E310 | 1680 | 1800 |

| 16M33D1980E310 | 1800 | 1980 |

| 20M33D2020E310 | 1850 | 2020 |

| 20M33D2210E310 | 2010 | 2210 |

| 12M55D2450E310 | 2200 | 2450 |

| 12M55D2700E310 | 2420 | 2700 |

| 16M55D2750E310 | 2500 | 2750 |

| 16M55D2900E310 | 2646 | 2900 |

| 16M55D3300E310 | 2900 | 3300 |

| 16M55D3600E310 | 3300 | 3600 |

-

-

In today’s industrial landscape, consistent and reliable power is critical. From manufacturing plants to data centers, u...

READ MORE -

In remote areas, access to a reliable power supply can often be a significant challenge. Whether due to geographic isola...

READ MORE -

Power outages can have significant impacts on businesses, from disrupting operations to damaging equipment or compromisi...

READ MORE -

In today's modern world, reliable access to electricity is critical for the functioning of homes, businesses, healthcare...

READ MORE

English

English Español

Español عربى

عربى