In today’s fast-paced industrial world, uninterrupted power is more than a convenience—it is a necessity. Manufacturing ...

READ MORECompared with the open-type generator set, the silent-type generator set has an additional device on its basis to make the generator soundproof and rainproof. The open-type generator set is enclosed with a shell, and the sound insulation material is adhered to the inner wall of the shell. At the same time, the air inlet and outlet should be left to allow the generator set to inhale air and dissipate heat. As a backup power source, diesel generator sets with silent boxes are mainly used in hospitals, hotels, high-end living areas, large shopping malls, and other places with strict requirements on environmental noise. It can also save customers a lot of money to build a generator room.

You can choose the brand you want

You can choose the type you want

+86-18652407919

+86-0514-86593686

+86-18944498005

-

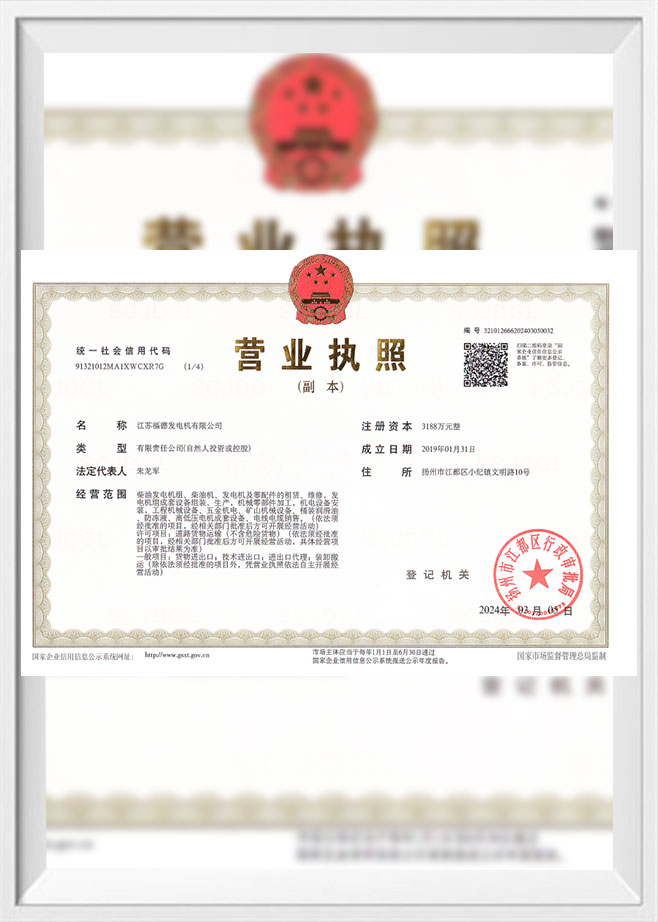

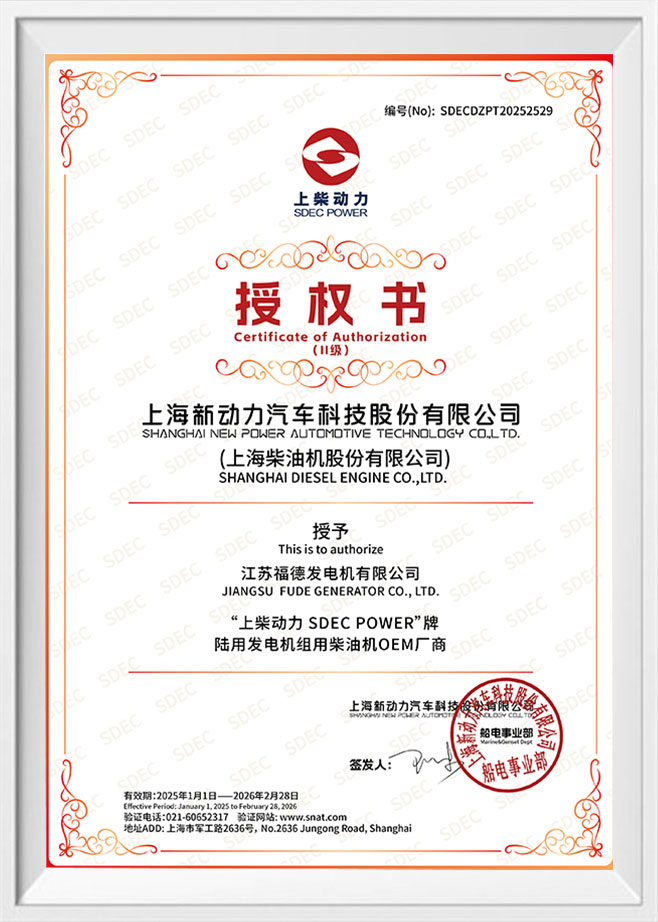

1

Support

Customization -

2

Own Factory,

Greatly Reducing

Costs -

3

Strict Quality

Control -

4

Strict Quality

Control -

5

Strong

Production Capacity -

6

More Considerate

Service

Request Quote

Request Quote

Portable silent diesel generator 10<kva≤100

| Portable silent diesel generator 10<kva≤100, suitable for small power demand places, suitable for camping, outdoor activities and small engineering projects. Low noise during operation reduces environmental interference. Its efficient fuel system and simple operation make it a flexible and economical power solution. |

Request Quote

Request Quote

Silent low-emission diesel generator 100<kva≤300

| Silent low-emission diesel generator 100<kva≤300, suitable for places with strict requirements on noise and emissions, the silent shell effectively reduces noise, suitable for hospitals, hotels, shopping malls and other occasions. Open the air inlet and outlet to ensure air circulation, maintain efficient heat dissipation of the unit, and ensure continuous operation in a quiet environment. |

Request Quote

Request Quote

Silent outdoor diesel generator 300<kva≤500

| Silent outdoor diesel generator 300<kva≤500, suitable for construction sites, large outdoor activities or temporary power supply occasions. It combines silent and efficient emission technology to reduce noise and exhaust emissions, and adapt to harsh outdoor environments. |

Request Quote

Request Quote

Silent camping diesel generator 500<kva≤800

| Silent camping diesel generator 500<kva≤800, it has a soundproof shell to ensure extremely low noise in outdoor environments, providing a quiet and comfortable power experience. It is an ideal choice for outdoor camping, field activities and emergency power supply. |

Request Quote

Request Quote

Silent outdoor diesel generator 800<kva≤1000

| Silent outdoor diesel generator 800<kva≤1000, suitable for providing power support in outdoor environment for a long time. It not only has powerful power output, but also has a silent shell to reduce noise interference, which is suitable for outdoor exploration, post-disaster recovery or temporary power supply. |

Request Quote

Request Quote

Silent emergency standby diesel generator 1000<kva≤1200

| Silent emergency standby diesel generator 1000<kva≤1200, it has the characteristics of low noise and low emission, ensuring stable and reliable power support in places with strict noise requirements such as hospitals and data centers. The closed shell effectively insulates against sound, and the air inlet and exhaust design ensures efficient heat dissipation of the equipment. |

Request Quote

Request Quote

Silent high-power emergency generator 1200<kva≤1500

| Silent high-power emergency generator 1200<kva≤1500, suitable for emergency power supply of large venues and important facilities. Silent design effectively reduces noise pollution, suitable for high-demand environments such as airports, large shopping malls, hospitals, etc. |

Request Quote

Request Quote

Prime Power

| Portable silent diesel generator 10<kva≤100 |

| Silent low-emission diesel generator 100<kva≤300 |

| Silent outdoor diesel generator 300<kva≤500 |

| Silent camping diesel generator 500<kva≤800 |

| Silent outdoor diesel generator 800<kva≤1000 |

| Silent emergency standby diesel generator 1000<kva≤1200 |

| Silent high-power emergency generator 1200<kva≤1500 |

-

-

In today’s industrial landscape, consistent and reliable power is critical. From manufacturing plants to data centers, u...

READ MORE -

In remote areas, access to a reliable power supply can often be a significant challenge. Whether due to geographic isola...

READ MORE -

Power outages can have significant impacts on businesses, from disrupting operations to damaging equipment or compromisi...

READ MORE -

In today's modern world, reliable access to electricity is critical for the functioning of homes, businesses, healthcare...

READ MORE

English

English Español

Español عربى

عربى