Comprehensive Application and Selection Guide for Movable Type Diesel Generator Sets

Jul 03, 2025

Content

- 1 What application scenarios are movable type diesel generator sets suitable for?

- 1.1 Temporary power supply for construction sites

- 1.2 Highway and railway construction projects

- 1.3 Field rescue and emergency rescue site

- 1.4 Open-air performances and large-scale event sites

- 1.5 Special operating areas of industrial and mining enterprises

- 1.6 Communication base stations and signal transmission guarantee

- 1.7 Power supply for agriculture and water conservancy facilities

- 1.8 Military exercises and field operations

- 1.9 Medical rescue and mobile detection systems

- 1.10 Temporary replacement or maintenance guarantee for urban power supply systems

- 2 What are the basic structural and functional characteristics of movable type diesel generator sets?

- 2.1 Diesel engine is the source of power

- 2.2 The generator converts mechanical energy into electrical energy

- 2.3 Control system realizes monitoring and management

- 2.4 The cooling system maintains temperature balance

- 2.5 Lubrication system reduces wear and extends life

- 2.6 Starting system achieves rapid ignition

- 2.7 Fuel tanks ensure continuous operation

- 2.8 Silence structure reduces noise impact

- 2.9 Mobile structure improves flexibility

- 2.10 Protective structure ensures stable operation

- 2.11 Multiple protection mechanisms ensure safety

- 2.12 Parallel and remote function expansion to adapt to multiple scenarios

- 2.13 Wiring and output structure meet various load requirements

- 2.14 Transportation and installation convenience are well considered

- 2.15 Diverse choices for different environments

- 3 How to choose a suitable mobile type diesel generator set according to usage requirements?

- 3.1 Identify the place of use and basic needs

- 3.2 Evaluate power requirements

- 3.3 Identify the voltage level and number of phases

- 3.4 Choose the right mobile method

- 3.5 Understand the structural and appearance protection design

- 3.6 Determine the control method and degree of automation

- 3.7 Pay attention to fuel type and fuel consumption level

- 3.8 Matching environmental adaptability

- 3.9 Understand the convenience of unit maintenance

- 3.10 Consider operating noise and emission requirements

- 3.11 Pay attention to brand service and qualification guarantee

- 3.12 Reasonable procurement and budget planning

- 4 Compared with fixed type units, what are the advantages of movable type diesel generator sets?

- 4.1 Higher deployment flexibility

- 4.2 Wider application scenarios

- 4.3 More convenient transportation and operation

- 4.4 More flexible investment and use methods

- 4.5 Higher space utilization efficiency

- 4.6 Noise control and environmental protection design are more adaptable

- 4.7 After-sales support and maintenance are more convenient

- 4.8 Emergency power supply capabilities are more responsive

- 4.9 Technological development promotes configuration diversification

- 5 What are the key factors affecting the operating efficiency of movable type diesel generator sets?

- 5.1 Diesel engine performance

- 5.2 The matching degree of the generator and the engine

- 5.3 Fuel quality

- 5.4 Load configuration and electricity usage

- 5.5 Cooling system efficiency

- 5.6 Air filtration and intake efficiency

- 5.7 Exhaust system smoothness

- 5.8 Lubrication system status

- 5.9 Control system configuration and maintenance

- 5.10 Ambient temperature, humidity, and geographical conditions

- 5.11 Daily maintenance execution

- 5.12 Frequency of use and operating habits

What application scenarios are movable type diesel generator sets suitable for?

Temporary power supply for construction sites

In the construction industry, construction sites are often located on the edge of cities or in remote areas, and are not yet connected to the municipal power grid, or the power supply is unstable. Movable type diesel generator sets can be flexibly deployed in construction areas at different stages and locations due to their strong independent power supply capabilities and structural design that is easy to transfer. Whether it is a tower crane, a mixer or a lighting system, a continuous power supply can be provided by the generator set to ensure the normal progress of the project.

The construction period of the construction site is long, and it may last for several months or even longer from infrastructure construction to decoration construction, and the power generation demand will also change with the stage. The mobile diesel generator set can configure power and transfer according to actual conditions, making resource utilization more flexible.

Highway and railway construction projects

During the construction of roads and railways, the working area is often in an open field with extended lines. Most of these areas do not have fixed power infrastructure. The trailerable, hand-pushed or vehicle-mounted structure design of the mobile diesel generator set enables it to move forward with the progress of construction and provide power support for welding, lighting, measuring equipment, etc.

Especially in special construction sites such as bridges and tunnels, there are power supply blind spots and high-risk working environments, and reliable mobile power supplies are essential. In addition, railway construction is frequently carried out at night, and the strong light lighting system must work continuously and stably. Mobile power stations can quickly provide the required electricity to improve the efficiency of night construction.

Field rescue and emergency rescue site

In emergencies such as natural disasters, sudden accidents, and power outages, the power supply system is often damaged, affecting the efficiency of rescue work. movable type diesel generator sets are often widely deployed at rescue and disaster relief sites because of their characteristics such as rapid start-up, stable operation, compact structure, and easy mobility.

Whether it is used to repair communication equipment, lighting systems, temporary medical tents, or to provide power support for emergency command vehicles and monitoring systems, the generator sets can respond quickly and be put into use. Some vehicle-mounted mobile power stations are also equipped with soundproof covers and automatic start devices, which are suitable for use in noisy or complex areas.

Open-air performances and large-scale event sites

Temporary large-scale events such as outdoor concerts, exhibitions, sports events, temple fairs, etc. have high requirements for the reliability and flexibility of the power supply system. The power load at the event site fluctuates greatly, and is often accompanied by high-power electrical appliances such as stage lighting, sound systems, and broadcasting equipment. At this time, it is a more appropriate solution to equip a mobile diesel generator set.

Hand-pushed or trailer-type mobile power stations can be reasonably placed according to the layout of the site to achieve zoned power supply for different functional areas. Some high-configuration mobile generator sets also have synchronous parallel functions, which can achieve power expansion and redundant backup, and improve the overall power supply stability.

Special operating areas of industrial and mining enterprises

In industrial operating units such as mines, quarries, and metallurgical enterprises, some zoned production lines are located in areas with weak grid coverage or temporarily no power supply conditions. At this time, the use of movable type diesel generator sets can be used as a transitional solution for local power consumption, providing power support for water pumps, exhaust fans, power tools, etc.

In open-pit mines or underground mining operations, space is limited and power wiring is difficult. Mobile power generation equipment can be transported to the operating surface via rail cars, trailers, or customized chassis to ensure the normal operation of key links.

Communication base stations and signal transmission guarantee

Some communication base stations are built in remote mountainous areas, islands or places with inconvenient transportation. In order to ensure signal coverage and communication services, it is often necessary to build a power supply system by yourself. In the early stage when there is no access to the power grid, movable type diesel generator sets become an important power supply solution for the initial operation or temporary guarantee of base stations.

When the communication system encounters lightning strikes, floods or other sudden power outages, mobile generator sets can temporarily replace the main power supply system to ensure normal communication services of the base station and reduce signal coverage blind spots.

Power supply for agriculture and water conservancy facilities

In agricultural activities such as agricultural irrigation, water pump drainage, and grain drying, there is often a shortage of power supply or seasonal operations. movable type diesel generator sets can be deployed on-site in cultivated land, orchards, canals, etc., with flexible power supply and easy transfer. Especially in emergency tasks such as drainage during flood season and irrigation during drought, mobile power generation equipment can quickly reach the mission area to ensure the efficient operation of agricultural equipment.

Military exercises and field operations

In military training, field camp construction and other occasions, there is a shortage of power supply in the field combat area. movable type diesel generator sets, with their portability and rapid deployment capabilities, have become an effective means of ensuring power supply for command systems, communication equipment, lighting and logistics living areas. Some special mobile power stations are equipped with multi-function operation panels to meet the use requirements of different voltage levels and output modes.

Medical rescue and mobile detection systems

In medical emergency sites such as mobile medical vehicles, emergency detection vehicles, quarantine areas in epidemic areas, stable power supply equipment is essential for equipment operation, lighting and environmental control. movable type diesel generator sets can be equipped with load protection and voltage regulation systems to provide continuous power for key equipment such as X-ray equipment, ventilators, oxygen generators, etc., and are an important part of mobile medical systems.

Temporary replacement or maintenance guarantee for urban power supply systems

During the maintenance of urban power systems, line inspections or regional power upgrades, mobile generator sets can be used as temporary alternative power sources to provide transitional power supply for important places such as residential buildings, traffic signal systems, hospitals, data centers, etc., reducing the impact of maintenance and construction on daily life. Especially during the transformation of power lines in old communities, movable type diesel generator sets can play a practical role in transitional power supply.

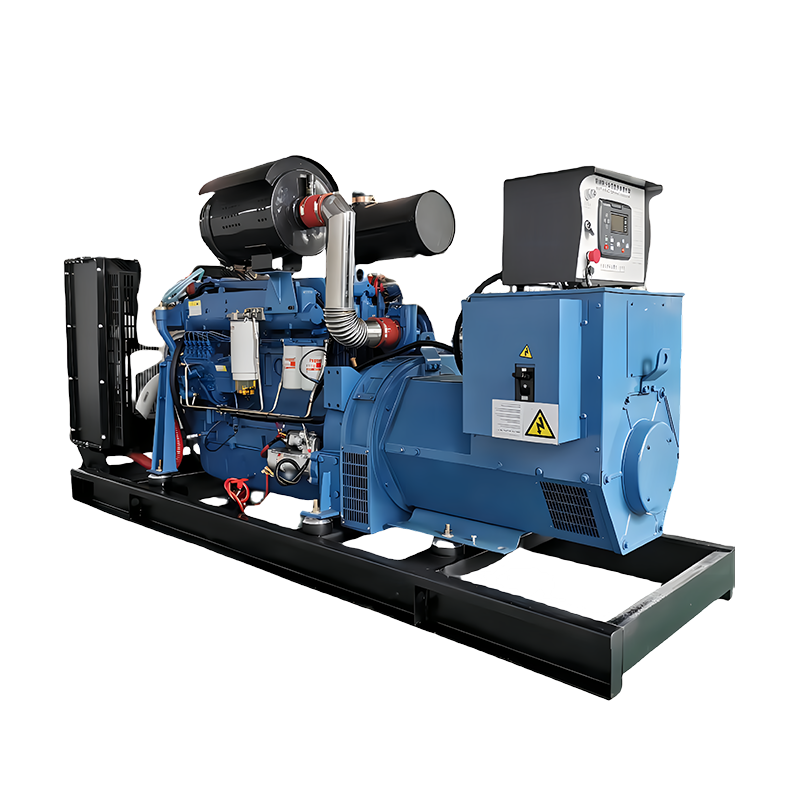

What are the basic structural and functional characteristics of movable type diesel generator sets?

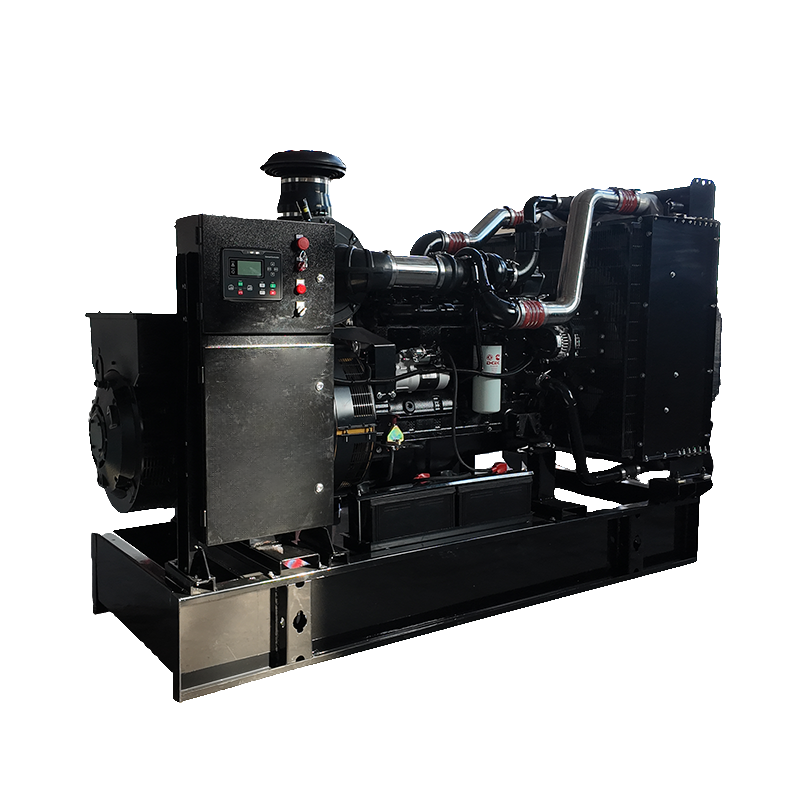

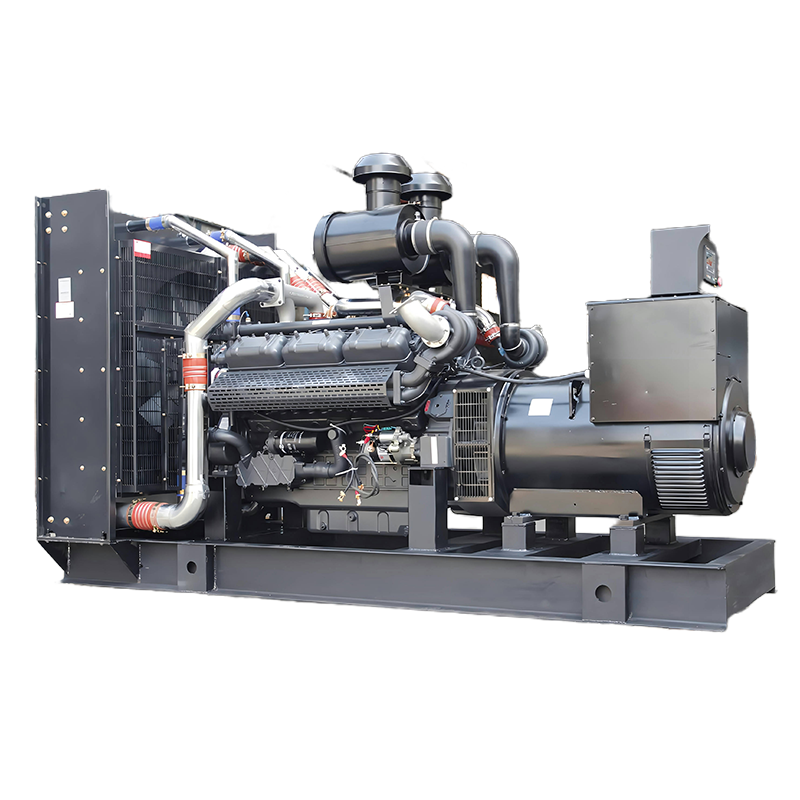

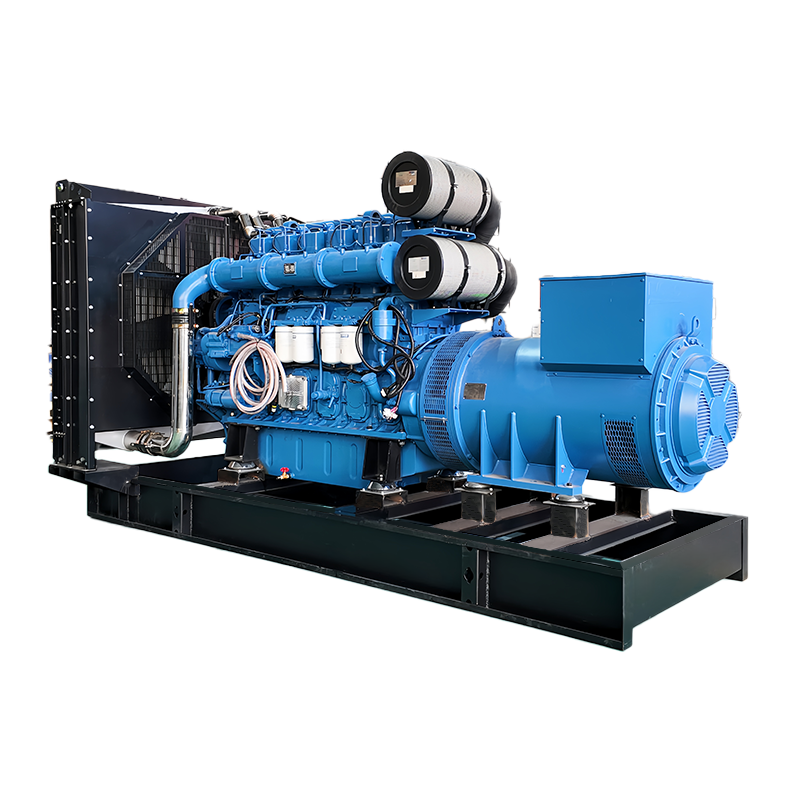

Diesel engine is the source of power

The core power source of movable type diesel generator sets is diesel engine, which generates mechanical energy by burning diesel, and then converts it into electrical energy by generator. Diesel engine has become a common configuration of mobile units because of its stable operation and relatively convenient fuel acquisition. The diesel engine used in the unit is usually divided into different displacement levels according to power requirements, and can maintain normal working state in complex environments such as low temperature and high humidity.

The generator converts mechanical energy into electrical energy

The power generation part is usually a brushless AC synchronous generator. This structure can output stable voltage and frequency and adapt to a variety of electrical equipment. It is installed on one side of the diesel engine and connected through a coupling to achieve speed synchronization. Some generator sets are equipped with automatic voltage regulation systems to maintain output voltage stability and reduce the impact of power grid fluctuations on load equipment.

Control system realizes monitoring and management

As the management center of the generator set, the control system undertakes tasks such as operation control, data monitoring, and fault alarm. Common functions include voltage, current, frequency display, engine speed and oil pressure detection. Most modern control panels use digital modules, have automatic start and stop functions, and can be connected to remote monitoring systems to improve ease of use and safety.

The cooling system maintains temperature balance

Diesel engines release a lot of heat when working. If they are not cooled in time, their performance will be affected or damage will occur. The cooling system mainly includes components such as radiators, water pumps, and fans. The common cooling method is water cooling, and some small units also use air cooling structure. The water temperature sensor monitors the engine status in real time to prevent risks caused by high-temperature operation.

Lubrication system reduces wear and extends life

The moving parts in the unit require lubricating oil to reduce friction, and the lubrication system provides oil circulation to avoid dry grinding of parts and cause failures. The system includes components such as oil pumps, oil filters, and oil pans, and monitors oil pressure through sensors, triggering alarms or automatic shutdowns when abnormalities occur.

Starting system achieves rapid ignition

movable type diesel generator sets usually use electric starting systems, which use batteries to power the starter motor to complete the starting process. Some small or special models are equipped with manual starting as an alternative, which is suitable for situations where batteries cannot be used. The automatic start function can also be triggered remotely in some control systems.

Fuel tanks ensure continuous operation

The fuel tank is a fuel supply guarantee device. It is generally designed inside the base or frame of the unit and has a certain volume to meet the fuel demand for long-term continuous operation. The fuel tank is equipped with an oil level gauge and overflow protection to ensure safety when refueling. High-power units are often equipped with external fuel tanks to extend the operating time.

Silence structure reduces noise impact

In order to adapt to environments with noise requirements such as residential areas, hospitals, and office places, some movable type diesel generator sets adopt a silent design, using soundproof shells, silencer cotton, and air intake and exhaust silencer systems. The operating noise is controlled within a certain range and does not affect the surrounding environment. At the same time, a good heat dissipation and ventilation structure is retained to ensure normal operation.

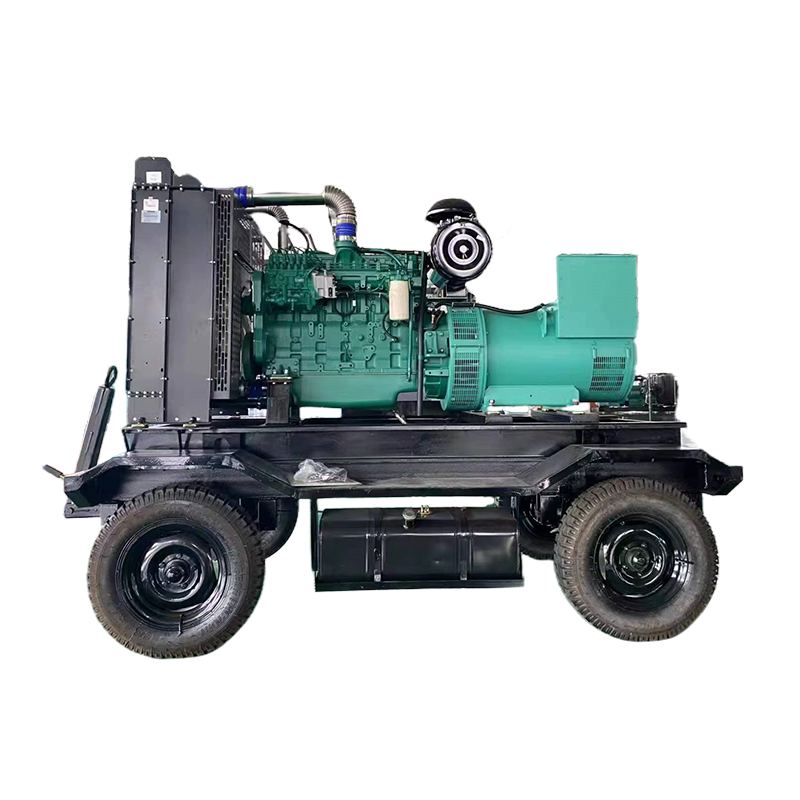

Mobile structure improves flexibility

Mobile generator sets are designed in a variety of ways, including hand-pushed, three-wheeled, four-wheeled, trailer-type, vehicle-mounted, etc., which are convenient for users to move freely according to the usage scenario. The chassis structure is sturdy and equipped with shock absorbers, brake systems, steering devices, etc., which are suitable for temporary power supply needs in different venues, such as construction sites, roads, mines, outdoor performances, etc.

Protective structure ensures stable operation

The overall structure is usually welded with steel plates and sprayed with anti-corrosion treatment, which has strong rain and dust resistance. The box structure has maintenance windows and inspection doors for regular maintenance and troubleshooting. Large silent units are also equipped with internal insulation and shock absorption devices to improve operational stability.

Multiple protection mechanisms ensure safety

movable type diesel generator sets are equipped with a variety of safety protection functions, including high temperature alarm, low oil pressure shutdown, overload protection, short circuit protection, oil shortage alarm, low voltage protection, etc. The protection system works in conjunction with the control system to intervene in time under abnormal conditions to avoid equipment damage and personal risks.

Parallel and remote function expansion to adapt to multiple scenarios

Some units have parallel functions, which can realize the coordinated power supply of multiple units, automatically distribute loads, and improve power supply capacity and stability. Units with ATS automatic switching modules can automatically enable the power generation system when the city power is off to ensure uninterrupted power supply. The remote monitoring module realizes real-time information collection and operation control through wireless or wired methods.

Wiring and output structure meet various load requirements

The output system is equipped with a variety of interfaces, including three-phase, single-phase, industrial sockets, etc., to adapt to the power requirements of different equipment. Some units are also equipped with special distribution boxes, protection switches and cable outlets, which are convenient for quick wiring and disassembly on site, especially suitable for temporary projects or multi-location construction needs.

Transportation and installation convenience are well considered

The unit structure takes into account the convenience of transportation and deployment. The chassis is equipped with hoisting holes and forklift holes. Large units support trailer traction, and the wheels have certain shock absorption functions. Light units are suitable for hand pushing or short-distance movement, and are suitable for various short-term or frequent handling conditions.

Diverse choices for different environments

The design of movable type diesel generator sets takes into account environmental differences such as temperature difference, humidity, and altitude. Some models are equipped with plateau adaptation devices, low-temperature starting devices or anti-dust structures to meet the power supply requirements of special areas such as plateaus, low temperatures, and deserts.

How to choose a suitable mobile type diesel generator set according to usage requirements?

Identify the place of use and basic needs

The first step in selecting a mobile diesel generator set is to identify the purpose. Construction, railway maintenance, highway maintenance, mining operations, emergency response, power repair, commercial activities and other scenarios have different requirements for the function and configuration of the generator. For example, on the construction site, more attention is paid to power output capacity and equipment durability, while outdoor activities prefer low-noise and highly portable units. Users with high frequency of use need to consider durability and continuous power supply capacity, while users with low frequency of use but requiring emergency response should give priority to starting performance and maintenance convenience.

Evaluate power requirements

Power is the core indicator for generator set selection and should be comprehensively calculated based on the actual load type. You can first list the rated power of all equipment and estimate the starting peak of the inductive load. For example, the instantaneous power of equipment such as air compressors and water pumps when starting may be 2 to 3 times the rated power. It is usually recommended to select a generator set with a rated power slightly higher than the actual demand to ensure that the equipment will not be overloaded during operation, and there is a certain reserve margin to cope with load expansion or emergencies.

Identify the voltage level and number of phases

Determine the output voltage and number of phases of the generator set according to the requirements of the connected electrical equipment. Most industrial electrical equipment uses a three-phase 380V power supply, while ordinary household or small appliances use a 220V single-phase voltage. If there is a need for both single-phase and three-phase power on site, a hybrid unit that supports dual voltage output can be selected. Some models also have voltage switching functions or customized voltage output functions, which are suitable for export or use in areas with special voltage standards.

Choose the right mobile method

The mobility of mobile generator sets is one of their important characteristics. According to ground conditions, transportation frequency and use sites, different mobile structures can be selected: such as hand-push type is suitable for small power equipment on flat sites; three-wheel or four-wheel chassis are suitable for short-distance traction and field deployment; trailer type has steering devices, axles, and brake systems, which are suitable for long-distance road transportation; vehicle-mounted units are directly fixed to special work vehicles, which are suitable for normal mobile work. The mobile method directly affects the efficiency of use and the convenience of deployment, and the selection needs to be evaluated in combination with actual operating conditions.

Understand the structural and appearance protection design

movable type diesel generator sets often operate outdoors, and structural protection is crucial. The open structure is suitable for indoor use or areas with good environment, and is easy to maintain, but it does not have rain and dustproof functions. The closed or silent type unit is equipped with a box shell, which has protection capabilities and can operate stably in rainy days or dusty construction environments. For places where low noise is required, such as schools, hospitals, and temporary event sites, it is recommended to use a silent type unit equipped with a silencer and sound insulation materials.

Determine the control method and degree of automation

The configuration of the control system affects the convenience of the unit's operation. The basic model is equipped with a manual start and shutdown control panel, which is suitable for manual supervision environments. The mid-to-high-end units are equipped with digital display, fault alarm and operation status monitoring functions, which are suitable for continuous operation and frequent management. Models with ATS (automatic transfer switch) can realize automatic switching with the mains, which is suitable for backup power needs. Units that support remote control and cloud monitoring are convenient for unattended or remote maintenance management, and are suitable for enterprises or institutions with relatively complete operation and maintenance management systems.

Pay attention to fuel type and fuel consumption level

Diesel generator sets have different fuel consumption rates depending on the engine model. When choosing, you should check the fuel consumption data under different load conditions, and estimate the overall fuel consumption cost in combination with the daily operating time. At the same time, you should also understand whether the unit supports long-term fuel tanks, auxiliary fuel tank connections or has an oil level alarm system, so as to facilitate timely refueling during long-term operation. For continuous operation scenarios, fuel consumption directly determines the economic efficiency of use.

Matching environmental adaptability

The temperature, humidity, altitude and other factors of the operating environment have a direct impact on the operation of the unit. The air in plateau areas is thin, so an engine that supports plateau mode should be selected to ensure sufficient combustion; cold start heaters and battery preheating devices should be selected in cold areas to ensure low-temperature starting capabilities; in humid or salt spray environments, attention should be paid to the protection level and overall corrosion resistance of the unit's electrical components. Environmental adaptability not only determines whether the unit can operate normally, but also affects its life and maintenance cost.

Understand the convenience of unit maintenance

When selecting a unit, you should consider the maintenance cycle, maintenance difficulty and availability of accessories. A unit with a reasonable structural design should be easy to replace air filters, oil filters, fuel filters and add coolant. Users should also understand whether the supplier provides standard maintenance manuals, regular inspection services, spare parts reserves and after-sales response mechanisms. Reasonable maintenance design can significantly reduce operating failures and downtime.

Consider operating noise and emission requirements

When used in urban, residential, medical, cultural and educational environments, unit noise control and emission standards are particularly critical. Silent units usually reduce noise levels through soundproof boxes, mufflers and structural vibration isolation. Different countries and regions have strict regulations on unit emissions, and it is necessary to ensure that the selected unit meets the corresponding standards, such as EU emission standards, EPA standards, etc. Some occasions may also require environmental protection certification or low noise certification before they can be put into use.

Pay attention to brand service and qualification guarantee

Give priority to brands with stable product lines, long-term operating history and complete service systems. Check whether the manufacturer has ISO quality system certification, engine and generator brand authorization, key component inspection reports, whole machine factory certificate, etc. At the same time, understand the distribution of its after-sales service outlets, warranty policies, technical training and response time. Reliable brands and services can provide more guarantees during use and reduce subsequent risks.

Reasonable procurement and budget planning

On the basis of clarifying the basic needs, the procurement cost and the use cycle should be comprehensively calculated. The investment in movable type diesel generator sets includes not only the purchase cost, but also fuel costs, maintenance, transportation expenses and operating personnel. If used for short-term projects or activities, you can also consider leasing solutions or modular parallel configuration to improve flexibility. For enterprises or construction units that use it frequently for a long time, it is recommended to invest in equipment with stable structure and precise control at one time to reduce the overall operating cost.

Compared with fixed type units, what are the advantages of movable type diesel generator sets?

Higher deployment flexibility

Fixed diesel generator sets are generally installed in specific locations, such as distribution rooms, equipment rooms or inside buildings. Once their locations are determined, they are not easy to change. movable type diesel generator sets have wheel structures or traction mechanisms, which can adjust the operating position at any time and are suitable for changing scenarios. This flexible deployment capability is particularly suitable for temporary construction, power repair, event site power supply, remote operations and other environments, and can quickly complete scheduling and layout according to actual conditions.

In emergencies, such as natural disasters causing regional power outages, mobile units can be quickly put into emergency response, shorten the power supply restoration time, and play the practical value of temporary power supply. In contrast, fixed units are restricted by the site and do not have the ability to respond and migrate quickly.

Wider application scenarios

movable type diesel generator sets are equipped with chassis, traction devices, support feet, mobile lamps, silent boxes and other configurations in their structure, making them suitable for more complex or changing environments. For example, in construction projects, the construction area is constantly changing, and the power distribution demand is adjusted accordingly. The use of mobile power generation equipment can improve work efficiency; in the field of road and railway maintenance, mobile units can operate along the line to meet the requirements of continuous power supply; they are also often seen in cultural and sports activities, outdoor exhibitions, music festivals and other occasions.

Fixed units are mostly used in factories, hospitals, data centers, commercial buildings and other places with high requirements for power supply continuity and stability and fixed locations. Although it has advantages in reliability, it is limited in multi-site scheduling applications.

More convenient transportation and operation

movable type diesel generator sets are designed with transportation needs in mind. Most of them have standardized trailer interfaces, brake systems, lighting signs, hoisting points and other configurations. They can be directly transported on the road or transferred by towing by operating vehicles. For engineering projects that require cross-regional electricity, one unit can be used cyclically between multiple operating points, saving equipment quantity and investment costs.

Modern mobile units are usually equipped with an integrated control panel, and some models support remote start, automatic fault diagnosis, parameter warning and other functions, which improves the convenience of on-site operation. Compared with fixed units that require professional installation, wiring and debugging, etc., mobile equipment is faster to start up and is suitable for temporary or non-professional technical support environments.

More flexible investment and use methods

Because they can be flexibly deployed, movable type diesel generator sets are more suitable for multi-task and phased project operation modes. For construction units, emergency support units or outdoor operation companies, using the same equipment to serve different projects can improve equipment utilization and reduce unit engineering costs.

In some low-frequency use or short-term demand scenarios, users can also choose to lease mobile units, which is more economical than purchasing fixed equipment. At the same time, the recycling and resale of equipment are also more convenient, with higher asset liquidity.

Higher space utilization efficiency

The installation of fixed units requires a separate foundation, sound insulation facilities, exhaust system and surrounding safety distance, which often occupies a lot of site resources, especially in urban projects with limited space. Mobile units mostly adopt an integrated design, with the engine, generator, control box, fuel tank, etc. all encapsulated in a standard box, which occupies a compact area and has a regular structure.

Some lightweight mobile units also adopt a folding structure, which can be unfolded when in use and stored when idle, further compressing the storage space. This space utilization advantage provides more possibilities for project site layout and logistics transportation.

Noise control and environmental protection design are more adaptable

Modern movable type diesel generator sets have optimized their structures in terms of noise reduction, such as configuring high-efficiency silencers, sound insulation boards, sound-absorbing cotton, air diversion systems, etc., so that their operating noise is controlled within an acceptable range, suitable for places that are sensitive to sound, such as medical points, campus activities, night construction, etc.

Some mobile units use environmentally friendly diesel engines and are equipped with exhaust treatment systems (such as DOC, DPF devices). The emission standards can meet local environmental protection requirements and adapt to the operating standards in municipal engineering or urban traffic areas. Compared with some old fixed equipment, its emission performance is more in line with the current environmental protection trend.

After-sales support and maintenance are more convenient

Since mobile power generation equipment needs to be frequently deployed and relocated, most manufacturers provide more convenient maintenance channels, such as quick-open doors, replaceable filter locations, centralized lubrication ports, external oil drain valves, etc., to facilitate users to complete daily maintenance under outdoor conditions. At the same time, the unit is often equipped with a digital display instrument to facilitate recording of operating time, maintenance cycles and fault prompts.

Compared with fixed units that have a strong dependence on machine rooms, cable systems, and infrastructure, mobile units have better independence and maintainability, and are suitable for users with lower maintenance capabilities or field operation conditions.

Emergency power supply capabilities are more responsive

In emergency scenarios, time and reaction speed are crucial. movable type diesel generator sets can be quickly mobilized after receiving instructions, usually without complex installation and commissioning processes, and can achieve rapid power supply after arriving at the site. Especially under emergency conditions such as natural disasters, power grid outages, and sudden accidents, their role is irreplaceable.

Some institutions, such as emergency management departments, power repair units, and communication operators, will always have multiple mobile units, which are stored by region to facilitate rapid response when needs occur. Fixed units can only serve a single location and cannot achieve multi-point switching functions.

Technological development promotes configuration diversification

With technological progress, the product forms of movable type diesel generator sets are becoming more and more abundant, meeting more professional applications. For example, mobile units with lighting towers can be used for night construction, units with welding machine interfaces are suitable for equipment maintenance scenarios, and units with multiple parallel interfaces can be quickly combined into temporary power stations to meet high power requirements.

There are also remote monitoring mobile generators with communication control interfaces, which can achieve remote positioning, operation data collection, fault diagnosis and command control through the platform. These new configurations continue to expand the functional boundaries of mobile units and play a role in more application areas.

What are the key factors affecting the operating efficiency of movable type diesel generator sets?

Diesel engine performance

The core of the mobile diesel generator set is the diesel engine, and its performance directly determines the power generation efficiency and operating stability. Parameters such as engine power matching, fuel injection accuracy, compression ratio, and combustion efficiency will affect the overall operating efficiency of the machine. If the engine performance declines, such as insufficient cylinder pressure, delayed injection, and insufficient lubrication, it will lead to incomplete fuel combustion, which will affect the power generation efficiency and even cause excessive fuel consumption or abnormal emissions.

In the selection and use process, it is a basic condition to ensure that the engine specifications match the load requirements. At the same time, regular inspections of the intake, exhaust, and fuel supply systems can effectively maintain the engine in an efficient operating state.

The matching degree of the generator and the engine

In the mobile diesel generator set, the matching relationship between the generator and the engine affects the power transmission efficiency. If the two are not matched reasonably, such as the engine output power is too high and the generator capacity is too small, it will cause overload operation and damage the equipment; conversely, if the generator capacity is too large and the engine power supply is insufficient, it will not be able to achieve efficient output.

The mobile diesel generator set manufacturer will configure the generator set according to the standard matching parameters. Users should avoid replacing core components privately when using it. If special-purpose equipment needs to be customized, it should be matched and designed by professional technicians to ensure that the equipment can reach a stable operating state under rated load.

Fuel quality

The quality of diesel has a profound impact on the operating efficiency of mobile units. Poor diesel may contain impurities, moisture or high sulfur content, which will form deposits in the injection system or combustion chamber, block the injector nozzle, affect the atomization quality, and ultimately lead to reduced combustion efficiency and increased engine wear.

Using clean diesel that meets national standards or manufacturer recommended specifications, combined with oil-water separators and regular cleaning measures, can effectively extend the service life of the engine and improve power generation efficiency. Especially in cold or humid environments, fuel quality problems are more likely to be exposed and have a greater impact on efficiency.

Load configuration and electricity usage

Reasonable load configuration is the key to ensuring unit efficiency. Long-term low-load operation will cause "light load operation", which will cause incomplete combustion of diesel engine fuel, increase carbon deposits, accelerate wear and reduce efficiency; while overload operation may cause the generator to overheat, trip or burn the coil.

It is recommended that users reasonably distribute the load according to the rated power of the unit, and try to control it within the operating load range of 70%-90%, which is the range where the diesel engine burns most fully and has a higher energy efficiency. At the same time, try to avoid frequent starting and stopping or large fluctuations in load status to reduce the fatigue operation of the unit.

Cooling system efficiency

movable type diesel generator sets are mostly operated in outdoor environments, and the effectiveness of the cooling system has a direct impact on the efficiency of the equipment. If the coolant circulation is not smooth, the fan efficiency decreases, or the water tank is scaled, the engine temperature will rise, thereby affecting its stability and power generation efficiency.

Keeping the cooling system clean, the coolant sufficient, and the fan drive normal are the basic requirements for maintaining system stability. In high temperature, plateau, dust and other environments, it is also necessary to strengthen the heat dissipation capacity, such as adding a secondary water tank or a high-power fan to ensure the cooling effect.

Air filtration and intake efficiency

Diesel engines have high requirements for intake quality. If the air filter is blocked, or there is a leak in the intake channel, and a large amount of dust is inhaled, it will cause poor air circulation and affect the combustion efficiency of the mixture. In addition, foreign matter mixed in the intake air may also cause wear on components such as the piston and cylinder liner. When the operating environment is harsh, the frequency of filter element replacement should be increased or a two-stage filter device should be used to keep the intake system unobstructed, thereby maintaining the engine's efficient operation ability.

Exhaust system smoothness

Poor exhaust will also affect engine efficiency. If the exhaust pipe is blocked, there is too much carbon deposit inside the muffler, or the exhaust back pressure is too high, it will interfere with the exhaust gas discharge process, reduce combustion efficiency, and accelerate the wear of engine components. The exhaust pipe and muffler should be checked and cleaned regularly to ensure smooth exhaust, especially in dusty and humid environments, where foreign matter or rust is more likely to accumulate, increasing exhaust resistance.

Lubrication system status

A good lubrication system helps reduce friction resistance, reduce energy consumption, and improve mechanical transmission efficiency. If the lubricating oil deteriorates, the oil volume is insufficient, or the circulation is not smooth, it will cause increased wear of engine parts and increase operating temperature, affecting power generation performance and efficiency. Selecting lubricating oil that meets the engine technical specifications and regularly replacing and checking the oil quality are important measures to maintain unit efficiency.

Control system configuration and maintenance

Modern movable type diesel generator sets are generally equipped with automatic control systems to monitor parameters such as voltage, current, oil temperature, water temperature, and operating time. An efficient control system can reasonably adjust the engine output under different load and environmental conditions to avoid unnecessary energy waste.

If the controller is improperly calibrated, the sensor fails, or the line contact is poor, the operating parameters may be abnormal, thus affecting the efficiency. Therefore, the control system should be maintained regularly to maintain logical stability and smooth communication to ensure that the unit operates efficiently in the set mode.

Ambient temperature, humidity, and geographical conditions

Mobile units often work outdoors or in the wild, and climatic conditions have a certain impact on efficiency. High temperature can easily cause equipment overheating, low temperature can increase the viscosity of the oil and make it difficult to start, high humidity environment can easily cause electrical components to short circuit or rust, and low pressure environment can affect combustion efficiency.

For different environmental conditions, corresponding technical solutions can be selected for adaptation, such as installing preheating devices in cold areas, adding sealing protection in wet areas, and strengthening the filtration system in dusty areas, so as to ensure that the operating efficiency does not decrease due to fluctuations in the external environment.

Daily maintenance execution

The operating efficiency of the equipment is inseparable from the maintenance status. Regular maintenance such as replacing filters, lubricating oil, checking line connections, cleaning the cooling system, and verifying instrument parameters can not only extend the life of the unit, but also ensure that the equipment is always in an efficient working state. Ignoring daily maintenance will accelerate the aging of various components, causing problems such as increased energy consumption, difficulty in starting, and reduced load capacity, affecting efficiency and safe operation.

Frequency of use and operating habits

The frequency of use and operating habits of the unit will also have a long-term impact on efficiency. Frequent start and stop, starting without preheating under low temperature conditions, and long-term idleness without maintenance will cause equipment performance to decline. The proficiency of the operator also affects efficiency. Mastering the correct start and stop steps, load switching timing, and fault identification capabilities will help improve the overall operation level.

English

English Español

Español عربى

عربى