Choosing the Best Silent Type Diesel Generator Set: A Comprehensive Buyer’s Guide

Jul 03, 2025

Content

- 1 1. What is a Silent Type Diesel Generator Set?

- 2 2. Key Factors to Consider When Choosing a Silent Diesel Generator

- 3 3. Additional Features to Look for in a Silent Diesel Generator

- 4 4. Installation and Maintenance Tips for Silent Diesel Generators

- 5 5. Cost Considerations: What Should You Expect to Pay?

1. What is a Silent Type Diesel Generator Set?

A Silent Type Diesel Generator Set (SDGS) is a specialized type of generator that utilizes advanced noise-reducing technologies to significantly lower the operational sound levels compared to traditional diesel generators. These generators are designed to provide the same power output and efficiency as conventional diesel models, but with a considerable reduction in noise pollution. Silent diesel generators are often used in settings where noise control is crucial, such as residential areas, hospitals, outdoor events, or in urban environments where strict noise regulations apply.

A.Difference Between Silent and Traditional Diesel Generators

Traditional diesel generators, while widely used for both backup and primary power generation, are known for their high noise levels. The noise generated is primarily caused by the engine’s combustion process and mechanical components such as the alternator, cooling system, and exhaust. The sound can be disruptive, especially in noise-sensitive environments.

Silent diesel generators are equipped with advanced features specifically designed to reduce noise. The main differences between silent and traditional diesel generators can be summarized as follows:

Sound Output (Noise Level)

Traditional Diesel Generators: These can produce noise levels ranging from 75 dB to 100 dB or even higher, making them disruptive, especially in residential or urban areas. For example, a traditional diesel generator running at full load in an industrial setting can create noise similar to the sound of a chainsaw or a passing truck.

Silent Diesel Generators: These generators are designed to operate at noise levels of 55 dB to 75 dB, which is roughly comparable to normal conversation or background noise. This makes them ideal for use in areas where minimizing noise is critical.

Noise Shielding Design

Traditional Diesel Generators: Traditional models have minimal or no built-in soundproofing. Most noise comes directly from the engine, alternator, and exhaust system.

Silent Diesel Generators: These generators are typically housed in specially designed enclosures made from sound-absorbing materials like steel and soundproofing panels. The enclosures reduce engine noise, and additional features such as vibration dampening systems help further reduce unwanted noise.

Engine Technology and Operation

Traditional Diesel Generators: Traditional generators may use older engine technologies with higher noise emissions, as they lack specific noise-reduction features.

Silent Diesel Generators: Modern silent models often feature low-noise engines designed to operate at lower revolutions per minute (RPM) or with optimized combustion techniques. These engines are often coupled with advanced mufflers and exhaust silencing systems to further minimize sound levels.

B.Principle of Silent Technology: Sound Insulation Materials, Low-Noise Engines, and More

The principle behind silent diesel generators is the integration of advanced noise-reduction technologies. These technologies focus on minimizing the noise produced by the generator, both at its source and during its operation. Let’s break down some of the core components of this technology:

Sound Insulation Materials

The enclosure of a silent diesel generator is made from sound-insulating materials that absorb and reflect noise. The most common materials used are:

Acoustic Panels: These are dense, vibration-damping panels placed inside the generator’s housing. They absorb sound energy and prevent it from escaping into the surrounding environment.

Rubber Gaskets and Seals: These components help seal joints and prevent vibration-induced noise from escaping through gaps in the enclosure.

Specialized Foam: High-density foam is often placed in strategic areas within the generator’s casing to absorb sound waves and further reduce noise levels.

Low-Noise Engines

A key feature of silent diesel generators is the use of low-noise engines. These engines are designed to reduce the noise generated during the combustion process. Key features of these engines include:

Engine Mounting: Silent diesel generators use vibration-dampening mounts to isolate the engine from the frame of the generator. This helps to reduce vibrations that contribute to noise.

Optimized Combustion Technology: Some engines incorporate advanced combustion techniques that reduce the intensity of the noise produced during fuel ignition. For example, engines may operate at lower RPMs, reducing the noise created by the engine’s moving parts.

Advanced Exhaust Silencing Systems

The exhaust system is another significant source of noise in a traditional diesel generator. In silent models, mufflers and silencers are integrated into the exhaust system to reduce exhaust noise. These components use baffles and resonating chambers to absorb and dissipate sound before it is released into the environment.

Soundproof Enclosure Design

The casing or housing around the engine and components of a silent diesel generator plays a crucial role in minimizing noise. The soundproof enclosure typically includes:

Double-wall construction with noise-absorbing insulation between the walls.

Ventilation openings designed to prevent the buildup of heat while still reducing noise.

Cooling systems that work quietly to avoid adding noise to the operation.

C.Application Areas of Silent Diesel Generator Sets

Silent diesel generators are highly versatile and can be used in a wide range of applications where traditional diesel generators would be disruptive. Let’s explore the various settings where silent diesel generators are most commonly employed:

Residential Areas

Silent diesel generators are perfect for residential use, especially in areas with noise regulations or in suburban neighborhoods. Whether for emergency backup power during blackouts or for remote homes that require a stable power source, these generators ensure that residents are not disturbed by loud, disruptive engine noise.

Commercial and Retail Environments

Businesses that rely on continuous power, such as data centers, restaurants, and offices, often choose silent diesel generators to ensure that their operations are not interrupted by power failures. In urban areas, where noise levels are often strictly regulated, having a silent generator ensures compliance with local ordinances while also maintaining operational efficiency.

Hospitals and Healthcare Facilities

In healthcare settings, where peace and quiet are critical for patient recovery, silent diesel generators provide a reliable power source without disrupting the environment. Whether used for backup power during an outage or in areas where grid power is unreliable, these generators help ensure that sensitive equipment remains operational without compromising the tranquility of the facility.

Outdoor Events and Festivals

Silent diesel generators are ideal for outdoor events, concerts, and festivals where noise can affect the experience of attendees. These generators are used to power stages, lighting, sound systems, and food stalls without interfering with the atmosphere of the event or disturbing nearby communities.

Construction Sites in Urban Areas

Urban construction projects can often be subject to strict noise control laws. Silent diesel generators are employed to provide power on construction sites while adhering to local noise regulations. They ensure that workers can operate machinery and equipment without causing excessive disturbance to the surrounding neighborhood.

Emergency Services and Disaster Relief

During disasters or emergency relief efforts, silent diesel generators are used to provide critical power to emergency response teams, shelters, and communication systems. The ability to operate quietly in sensitive environments while delivering reliable power is a major advantage for these generators.

2. Key Factors to Consider When Choosing a Silent Diesel Generator

A. Power Output and Capacity

How do you calculate the power output you need?

When choosing a generator set, the first step is to calculate the total power requirements. This usually includes the total power (in kilowatts kW or kVA) of all the equipment that needs to be powered. The basic steps are as follows:

List all the electrical equipment: such as air conditioners, computers, lighting, power tools, refrigerators, etc.

Determine the power rating (W or kW) of each device.

Consider the starting power: some equipment (such as motors, refrigerators) may require 2-3 times more power when starting than when running.

Add up the total requirements: For example, if the total power of the equipment you need to power is 8kW, plus a 30% starting margin, it is recommended to purchase a generator set with an output of no less than 10.4kW.

Recommended tools: Use the online "Generator Power Calculator" to help quickly estimate the power required.

Avoid oversizing or undersizing

An undersized generator: It cannot meet all load requirements, may cause frequent overloading, and even damage equipment and the generator itself.

Oversized generator: Although it has sufficient power, it will cause fuel consumption, reduced efficiency, increased operating costs, and may also cause "wet pile" phenomenon (diesel is not fully burned) due to light load operation.

Best strategy: Choose a silent generator with an output power slightly higher than the actual demand by 10%-20%, leaving room for future expansion.

Continuous load vs. peak load matching

Continuous load: refers to the power demand during normal operation, which should usually match the rated power of the generator.

Peak load: refers to the short-term high power demand when the equipment starts. Make sure the generator can withstand this short-term load.

For example: air conditioners, compressors, and elevators will consume higher than normal current at the moment of startup.

B. Noise Level (dB Rating)

When choosing a silent diesel generator, noise control is a very important consideration, especially in urban residential areas, commercial places or sound-sensitive environments. Silent generators are designed to solve the problem of traditional diesel generators with loud operating noise and disturbing people.

Noise standards for silent diesel generators

Silent diesel generators control the sound during operation within a reasonable range by adopting noise reduction technologies such as sound insulation cotton, noise reduction fans, and optimized exhaust design. It is generally believed in the industry that noise levels between 55 and 75 decibels (dB) can be classified as "silent".

Generators with 55 to 65 dB are "low noise levels" and are suitable for places with strict environmental noise requirements, such as residential areas, office buildings, schools, hospitals, libraries, etc. This level of generator basically cannot hear obvious engine sound a few meters away, which will neither affect work nor interfere with life.

Silent generators with 65 to 75 dB are suitable for areas with high noise tolerance, such as factories, warehousing and logistics, construction sites and agricultural breeding bases. This noise is equivalent to the sound of an ordinary household vacuum cleaner, and generally does not affect construction site operations or outdoor use.

Once the noise exceeds 80 decibels, the generator can hardly be considered "silent". Such high decibels will not only cause dissatisfaction among surrounding residents, but may also violate the local government's noise emission standards, and even bring the risk of administrative penalties or suspension of work.

Before purchasing a silent diesel generator, be sure to check the official noise level certification of the equipment or the user's actual measured data to ensure that the decibel value during operation meets the standards of the usage scenario.

How to understand the decibel (dB) value and its actual impact?

"Decibel" (dB) is a logarithmic unit used to measure the intensity of sound. Because it is a logarithmic scale, for every 10 dB increase, the actual auditory volume will feel about twice as loud as before. This means that the increase from 50 dB to 60 dB is not a small change, but a very obvious improvement in hearing.

For example:

A 30 dB environment is equivalent to a bedroom late at night, which is very quiet;

50 dB is the volume of a normal person talking;

65 dB is equivalent to the sound of a vacuum cleaner running;

75 dB is similar to the traffic noise on the main roads in the city;

85 dB is similar to nightclubs, bars or crowded subway cars.

In the environmental protection regulations of some countries or regions, long-term noise exposure exceeding 85 dB is considered harmful to hearing. Therefore, when choosing a silent diesel generator set, you should ensure that long-term use will not bring hearing health risks.

How to choose the noise level according to the use environment?

Different use environments have different requirements for the noise level of generators. The following are some typical selection references:

Residential areas, city centers, schools and other densely populated or quiet places should give priority to high-silent generators with a noise level of less than 60 dB during operation. Such products usually use thickened sound-absorbing layers, double-layer noise reduction shells, and can even be equipped with "ultra-silent covers".

In special sensitive areas such as hospitals, laboratories, and nursing homes, the impact of noise frequency types (low frequency, high frequency) on human psychology and nervous system needs to be considered. It is recommended to use low-noise and silent models with national certification.

Construction sites, factories, or mining areas can accept 65~75 dB equipment because there is a certain amount of noise in the working environment. At this time, noise is not the most important consideration, but it is still recommended to control it within the range acceptable to workers to ensure operational safety and comfort.

C. Fuel Efficiency and Runtime

Fuel efficiency and run time determine the economy and practicality of diesel generator sets during long-term operation, especially for scenes that require continuous power supply, such as engineering projects, communication support, and outdoor camps. Choosing a silent generator with high fuel efficiency and long run time will effectively reduce operating costs.

How to choose a silent generator that is fuel-efficient and lasts long?

To measure whether a diesel generator is "fuel-efficient", two technical parameters are mainly considered:

Unit fuel consumption (L/h): that is, the diesel consumption per hour under a certain load (such as full load or 75% load). The smaller the value, the more energy-saving it is.

Fuel efficiency (kWh/L): that is, how many kilowatt-hours of electricity can be generated per liter of diesel. This indicator can more comprehensively reflect the performance of the generator.

In addition to numerical indicators, the fuel system configuration of the model is also crucial. For example:

Electronic fuel injection system (EFI): optimizes combustion efficiency by precisely controlling the amount of diesel injection;

Common Rail technology: makes combustion more complete through a high-pressure injection system, reducing fuel consumption and emissions;

Turbocharging technology: improves intake efficiency, makes combustion more thorough, and also improves energy efficiency.

High-quality silent generator brands usually optimize fuel in the internal structure and control system of the engine to ensure high efficiency and low consumption during continuous operation.

Comparison of fuel efficiency of different brands and models

Even with the same power, the fuel economy of different brands or models may vary significantly. For example:

Two 50kVA silent diesel generators, under full load:

Brand A consumes 8 liters/hour;

Brand B reaches 10 liters/hour.

Assuming 10 hours of operation per day, Brand B consumes 20 liters of diesel more than Brand A per day. Calculated at 8 yuan per liter of diesel, the difference is 160 yuan/day, and the cost difference of 32,000 yuan for 200 days a year.

When comparing models, you can't just look at the price and power, you must also check the fuel consumption index and operating efficiency to make the most cost-effective choice in the long run.

The relationship between fuel tank capacity and continuous running time

The continuous running time of the generator is not only related to the fuel consumption, but also closely related to its own fuel tank capacity. Generally speaking, the larger the fuel tank capacity, the longer the equipment can work continuously without refueling, which is particularly suitable for unattended or continuous operation occasions.

For example, a silent diesel generator:

Equipped with a 120-liter fuel tank;

Fuel consumption at full load is 8 liters/hour;

It can run continuously for about 15 hours without manual refueling.

In scenarios such as emergency power supply, field camps, and base station power supply, this long endurance can significantly improve operating efficiency and power supply stability.

Some high-end models also support:

External fuel tank system: can be connected to a large-capacity external fuel tank to achieve longer battery life;

Automatic refueling function: used in conjunction with the fuel storage system, automatically replenish when the fuel level is below the warning line, ensuring that the equipment operates uninterruptedly around the clock;

Remote fuel level monitoring: through the Internet of Things platform, the remaining fuel level and refueling cycle can be checked at any time to improve management efficiency.

3. Additional Features to Look for in a Silent Diesel Generator

A. Portability

Lightweight vs. fixed generators

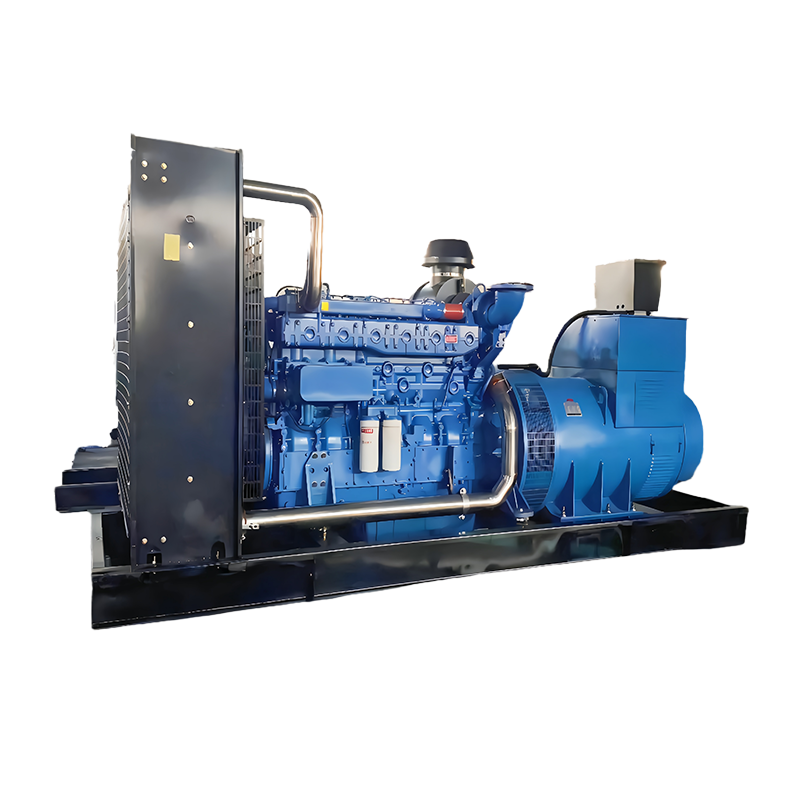

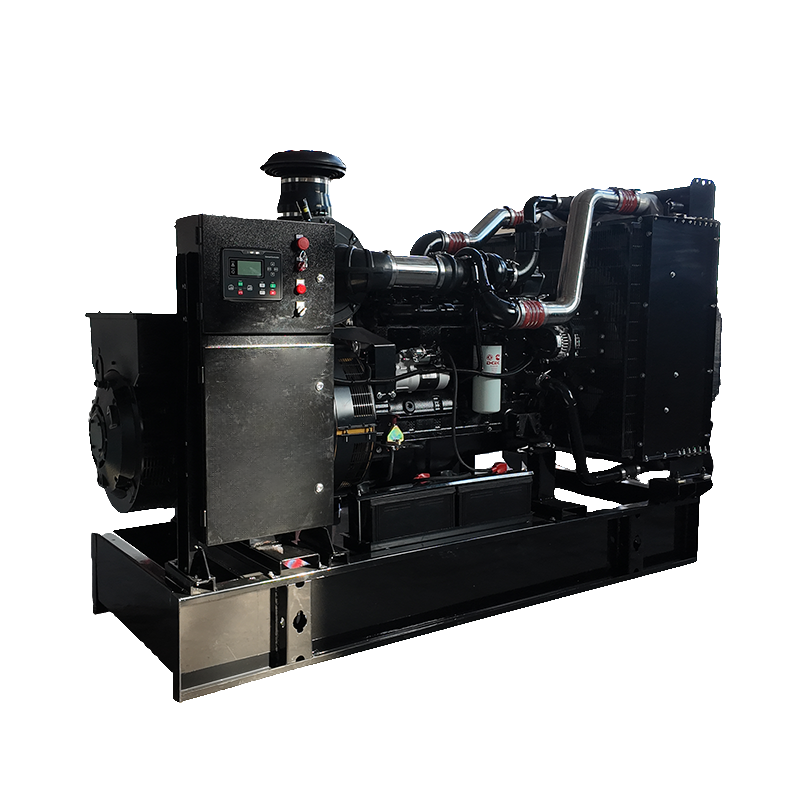

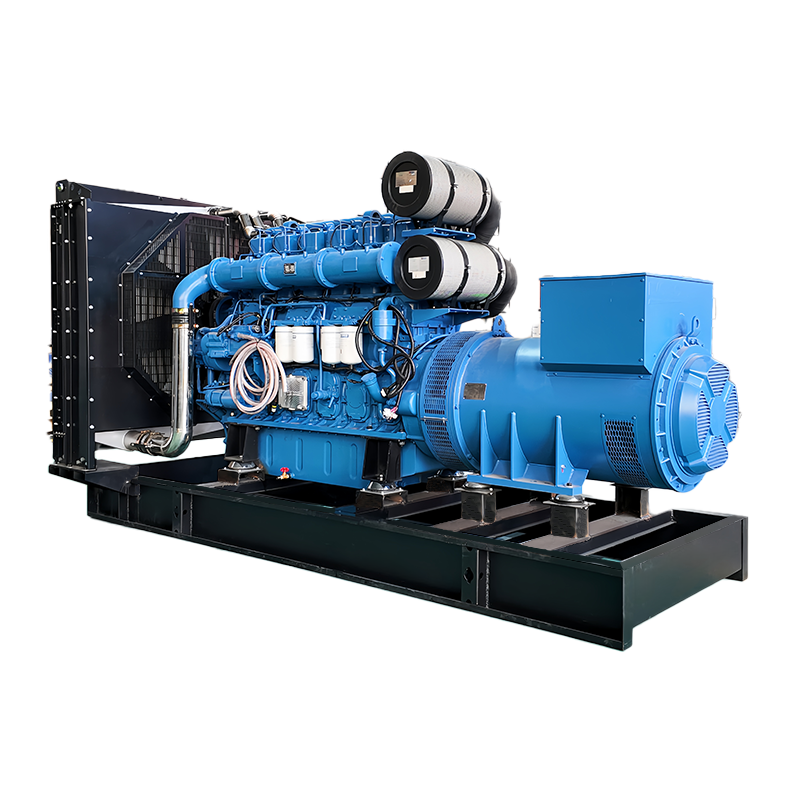

Silent diesel generators are mainly divided into two structural designs:

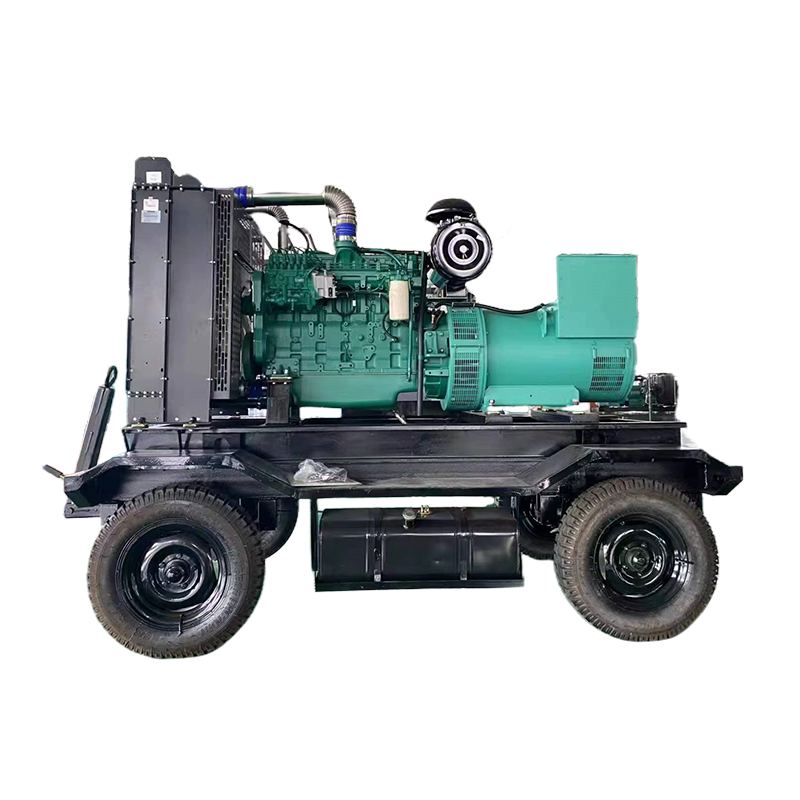

Lightweight (portable): usually small in size, with wheels or foldable handles, suitable for temporary operations or users who need to move frequently. For example: outdoor construction, power repair, emergency rescue, camping, etc.

Fixed: large in size and heavy in weight, suitable for long-term deployment in a fixed location, such as hospitals, data centers, communication base stations, factories, etc., pursuing stronger power and more stable operation.

Advantages of portable design

Flexible deployment: For locations where power demand changes frequently (such as multiple construction sites, temporary stages, mobile shops, etc.), portable generators can be quickly deployed and recovered, saving time and labor costs.

Convenient transportation: Small silent generators can be easily loaded into pickup trucks or small trucks, suitable for daily cross-regional deployment.

Convenient maintenance: The portable structure is more convenient for on-site maintenance or return to the factory for inspection.

Tip: If your usage scenario involves "multi-point power supply" or "temporary deployment", it is strongly recommended to give priority to models with high mobility and modular design.

B. Automatic Voltage Regulator (AVR)

The role and importance of AVR

AVR (Automatic Voltage Regulator) is an automatic voltage regulator. Its main functions are:

Stabilize output voltage: Even if the load increases or decreases suddenly, AVR can adjust the generator voltage to maintain stable power supply;

Prevent voltage fluctuations: Effectively avoid voltage shocks that damage electrical equipment, especially for computers, communication equipment, and precision instruments;

Prolong equipment life: Long-term stable power supply helps to extend the service life of connected electrical equipment.

In the absence of AVR, once the generator load fluctuates, the output voltage may be too high or too low, burning sensitive electrical appliances or causing data loss.

How to choose a silent generator with AVR?

Check whether the product manual or nameplate clearly states "with AVR function" or "Voltage Regulation: Automatic";

Prefer models with digital display control panels, which can display voltage, current and frequency in real time, making it easier to monitor voltage stability;

High-end models usually support "digital AVR", which is faster, more accurate and more compatible.

C. Safety Features

If the generator lacks the necessary safety protection mechanism during long-term operation, electrical failure or mechanical damage is very likely to occur. Therefore, it is crucial to choose a silent diesel generator with comprehensive safety functions.

Common and important safety features include:

Overload Protection: When the load exceeds the generator capacity, the output is automatically cut off to prevent the generator or electrical equipment from burning;

Low Oil Alert: When the oil level is insufficient, the system automatically issues an alarm or shuts down the engine to avoid serious wear or "burning cylinder" due to poor lubrication;

Overheat Protection: When the body temperature is too high, an alarm or shutdown protection is issued to effectively prevent the engine from being damaged by high temperature;

Short Circuit Protection: Avoid sudden circuit short circuits that cause high voltage shocks or fires;

Automatic flameout system: Once a fault or danger signal is detected, it can automatically shut down to avoid further accidents.

How to ensure the safe operation of the equipment?

Choose products with multiple protection mechanisms and check them regularly to see if they are working properly;

Choose models with "intelligent control panels" to monitor voltage, current, oil level, water temperature and other conditions in real time;

Configure necessary "remote alarm and shutdown functions" to facilitate unattended use.

It is especially recommended to choose models with complete certifications such as CE, ISO, EPA, TUV, etc., indicating that they meet international electrical and safety standards.

D. Durability and Build Quality

When operating in complex outdoor and industrial environments, the generator faces not only power load, but also many tests such as temperature difference changes, rain, dust, vibration, corrosion, etc. Therefore, when purchasing, you should pay attention to its structural strength and material durability.

High-quality materials determine lifespan

Corrosion-resistant shell: powder-coated steel plate, stainless steel or galvanized shell to prevent rust and corrosion, especially suitable for high humidity, seaside, rain and snow areas;

High-strength alloy base: ensure that it is not easy to deform during transportation and hoisting;

Industrial-grade radiator and filtration system: improve stability in high temperature and dusty environments.

Anti-vibration structure design

High-quality silent generators adopt **"elastic shock-absorbing structure"**, which uses shock-absorbing pads, floating supports and other technologies to alleviate mechanical vibrations during engine operation, reduce noise and avoid damage to the body;

For users who need to transport or use it on construction sites, anti-vibration performance is particularly important, which can greatly extend the equipment maintenance cycle.

Brand and manufacturing process affect overall quality

Silent generators of big brands usually implement higher quality control standards during the manufacturing process. The sealing of the unit, internal wiring process, welding processing, etc. all reflect high reliability, thereby achieving long-term stable operation.

4. Installation and Maintenance Tips for Silent Diesel Generators

A. Installation Process

Preparation before Installation

Before installing the silent diesel generator, you first need to make comprehensive preparations for the installation site and the equipment itself. The installation location should be selected in an area with good ventilation, solid ground, and away from flammable and explosive materials. Although the silent box has certain insulation and noise reduction functions, the generator will still generate a lot of heat during operation, so it is necessary to ensure sufficient heat dissipation space to prevent the unit from overheating.

The foundation must be flat and solid. It is best to use a thick concrete platform as the foundation to prevent vibrations generated during operation from causing displacement or structural damage. If installed outdoors, rain protection measures should be taken, such as installing a protective shed or choosing a model with a waterproof grade. At the same time, drainage ditches or floor drains should be set up to prevent rainwater from backflowing and causing electrical short circuits or water ingress to the equipment.

In terms of electricity, the power supply line and control system wiring need to be planned in advance. According to the power and purpose of the generator, the load wiring port, grounding device and backup power interface should be laid out in advance, especially for models equipped with an automatic switching system (ATS), it is necessary to ensure that the automatic switching function between the main power supply and the generator is connected reasonably and sensitively.

Installation steps and debugging process

The installation process generally includes several key links, including unit placement, electrical connection, control system access, and trial operation and debugging.

Use appropriate lifting equipment (such as a crane or forklift) to place the generator set securely on the preset foundation to avoid bumping the body or damaging the mute box. After positioning, perform leveling to ensure that the equipment will not cause oil deflection or uneven coolant distribution due to tilting during operation.

The subsequent electrical connection work requires special care and must be operated in accordance with the circuit diagram and technical parameters provided by the equipment. Connect the output end of the generator to the electrical equipment, and ensure that all wiring points are firmly connected, and the wire selection meets the current carrying standard. At the same time, the equipment must be grounded to prevent leakage and lightning risks. If the generator needs to start automatically, the battery, electronic control circuit and ATS system should also be connected.

After completing the basic installation, check whether all oils and liquids are filled in place before the first trial run, including diesel, oil and coolant. It is recommended to run at no load for the first time, and carefully observe whether the equipment starts smoothly, and whether there are abnormal sounds, odors or vibrations. After the equipment runs stably, gradually connect the load and test whether various parameters are normal, including voltage, frequency, oil pressure, water temperature, etc. At the same time, check whether the alarm system is sensitive and reliable.

Can it be installed by yourself?

Although some small silent diesel generators have "plug and play" functions, the overall diesel generator system structure is complex, involving multiple fields such as power system, fuel system, cooling system, exhaust system and automatic control system. Therefore, if the user lacks electrical basics or is not familiar with the structure and principle of diesel engines, it is strongly recommended to entrust professional technicians or the manufacturer's after-sales service team to install it.

Professional installation is not only more in line with safety regulations, but also can avoid equipment damage, performance degradation, and even fire, electric shock and other serious safety accidents caused by incorrect wiring or improper installation. At the same time, the warranty terms of many manufacturers also require installation by authorized technicians, otherwise you may not be able to enjoy subsequent warranty services.

B. Maintenance inspection and maintenance recommendations

Daily inspection and regular maintenance points

Although silent diesel generators have relatively high stability, scientific and reasonable maintenance is essential to ensure their long-term stable operation and extend their service life. Maintenance can be divided into several levels: "daily inspection", "periodic maintenance" and "major overhaul".

In daily use, the fuel level and coolant reserve should be checked before starting the equipment each time to ensure that there will be no difficulty in starting or high temperature alarm due to lack of liquid. At the same time, check whether there are signs of oil leakage, water leakage, and leakage of electricity on the body, and observe whether there is water accumulation or oil stains around. After the equipment is started, it should be monitored for abnormal noise, check whether the exhaust is smooth, whether there is any different-colored smoke, and observe whether the voltage fluctuates.

After each period of use, it is necessary to replace or clean it according to the cumulative running hours. For example, after running for about 100 hours, it is recommended to replace the engine oil and clean or replace the oil filter; after running for about 250 hours, the diesel filter needs to be replaced and the air filter needs to be cleaned; after running for 500 hours or more, the air filter needs to be completely replaced, and key components such as the injector and injection pump need to be checked and calibrated.

As the key power source for starting the generator, the battery should also check its voltage status every month. If it is an ordinary lead-acid battery, the electrolyte needs to be replenished regularly. The fan belt and water pump belt should be checked regularly for looseness or wear to avoid failure of the cooling system due to belt breakage.

How to extend the service life of the generator?

In order to keep the silent diesel generator running stably for a long time, in addition to regular maintenance, some best practices in use and management should be followed:

Regular start-up test: Even if it is a generator used as a backup power source, it should be started at least once a month and run for 10 to 15 minutes under load to keep the engine in good condition and prevent rust on the parts and blockage of the oil circuit.

Control the load ratio: Diesel generators should be operated between 70% and 80% of the rated power as much as possible. Too light a load can easily cause carbon deposits, while too heavy a load may damage the motor or overheat and stall.

Use regular oil products: Avoid using low-quality diesel and engine oil mixed with water and impurities. Poor-quality fuel will accelerate the wear of the injectors and cylinders.

Keep the body clean: Wipe the surface of the generator regularly to prevent dust and oil from adhering to poor heat dissipation or corroding the metal surface.

Record equipment operation logs: After each use or maintenance, data such as operating time, load conditions, maintenance items, etc. should be recorded to facilitate future troubleshooting and equipment management.

5. Cost Considerations: What Should You Expect to Pay?

A. Analysis of the price range of silent diesel generators

The price range of silent diesel generators is large, mainly depending on the power of the generator, brand reputation, additional functions and purchase channels. Generally speaking, small silent diesel generators (power of about a few kilowatts) are relatively low-priced and suitable for home, shop or small office use. The price is usually around a few thousand yuan to ten thousand yuan. However, the price of medium and large industrial silent diesel generator sets (power ranging from tens of kilowatts to hundreds of kilowatts or even higher) will rise sharply, and may reach tens of thousands to hundreds of thousands of yuan or even higher.

For example, a 10-kilowatt household silent diesel generator may have a market price between 10,000 yuan and 20,000 yuan; while a commercial or industrial generator of about 100 kilowatts often has a price ranging from 50,000 yuan to 150,000 yuan. The price of large generator sets (200 kilowatts and above) may easily exceed hundreds of thousands of yuan depending on the brand and configuration.

B. Main factors affecting price

Power

Power is the most direct factor in determining the price of diesel generators. The greater the power, the higher the engine displacement, the more complex the required materials and manufacturing processes, and the cost will naturally increase. Large units are not only powerful, but also usually equipped with more complete cooling, lubrication and safety protection systems, and the price will rise accordingly.

Brand and quality

Well-known brand generators usually have more advanced technology, stricter quality control and complete after-sales service, so the price is higher, but they are also more reliable and durable, and the user experience is better. In contrast, some domestic or niche brand models are cheaper, but the quality and after-sales guarantee may not be stable enough, and users need to weigh the price and risk.

Additional functions and configurations

The silent effect is an important selling point of this type of generator. Models equipped with high-efficiency silencers and shock absorbers are naturally more expensive than ordinary diesel generators. In addition, some models support advanced configurations such as automatic start-stop function, remote monitoring, intelligent control panel, automatic switching (ATS), etc., which will also increase the overall procurement cost.

Supporting facilities such as rain covers, special transport racks, cold start devices, etc. will also be reflected in the final price.

Purchasing channels and after-sales service

Purchasing through formal channels (factory direct sales, authorized agents) generally has more transparent prices and perfect after-sales guarantees. Although e-commerce platforms or second-hand markets may be cheap, there are risks in quality and service.

C. Long-term maintenance and operating costs

In addition to the initial purchase cost, silent diesel generators are also accompanied by certain long-term maintenance and operating costs. Users must consider these expenses when making budgets to avoid the use experience being affected by cost overruns during use.

Fuel cost

Diesel, as the main fuel for generators, is a fixed expense for long-term operation. Diesel prices are affected by factors such as international oil prices and regional supply and demand, and prices fluctuate greatly. Depending on the power and frequency of use of the generator, fuel expenses may become the largest cost item in daily operations.

For example, when a medium-sized generator is running at full load, the diesel consumption per hour may reach 5-15 liters, and the fuel cost of long-term operation cannot be underestimated.

Regular maintenance costs

In order to ensure the performance and life of the generator, consumables such as engine oil, filter elements, belts, etc. must be replaced on time, and necessary inspections and debugging must be carried out. Maintenance costs include consumables and labor costs, which generally account for 5%-10% of the equipment purchase price per year.

If the operating environment is harsh (such as dust and humidity), the maintenance frequency and cost will increase accordingly.

Spare parts replacement and repair costs

As the use time increases, some parts such as injectors, starter batteries, cooling system components, etc. will wear and need to be replaced or repaired. The price of spare parts is greatly affected by the brand and model. High-quality brand spare parts are relatively expensive, but more durable.

Operation and management costs

Include operator salaries, electrical equipment management costs, regular inspection costs, etc. For high-power generator sets, full-time personnel are usually required to be responsible for daily management and maintenance.

D. How to make a reasonable budget?

Clearly determine the required power: Choose the power reasonably according to the actual load demand to avoid waste caused by "oversized" units, and do not choose insufficient power to cause frequent overload of equipment.

Choose the right brand and configuration: Consider quality, after-sales and budget comprehensively, give priority to brands with good reputation and mature technology, and decide whether to purchase additional intelligent monitoring or automation equipment based on the budget.

Reserve maintenance and operating expenses: In addition to the procurement budget, reserve at least 10%-15% of annual operating and maintenance expenses for fuel, maintenance, spare parts replacement, etc. Consider the use cycle and return: When purchasing, in addition to paying attention to the one-time investment, pay more attention to the equipment's service life, energy-saving performance and failure rate, and comprehensively evaluate the cost-effectiveness.

English

English Español

Español عربى

عربى