Mobile Silent Diesel Generator Full Power Range Application Guide

Jul 03, 2025

Content

- 1 Product definition: What is a mobile silent diesel generator set?

- 2 Comprehensive upgrade of product matrix: 7 power ranges, full scene coverage

- 2.0.1 10<kVA≤100: Portable outdoor quiet power supply

- 2.0.2 100<kVA≤300: A powerful tool for temporary power supply for small and medium-sized construction

- 2.0.3 300<kVA≤500: Outdoor large-scale camping and engineering applications

- 2.0.4 500<kVA≤800: Multi-point power supply guarantee for industry and construction

- 2.0.5 1000<kVA≤1200: First choice for emergency backup scenarios

- 2.0.6 1200<kVA≤1500: Heavy-duty industrial and special demand solutions

- 3 Six advantages of mobile silent generators

- 4 Multi-scenario application, helping to ensure power supply in multiple industries

- 5 Environmental protection and energy saving: coexistence of low emissions and high fuel efficiency

Product definition: What is a mobile silent diesel generator set?

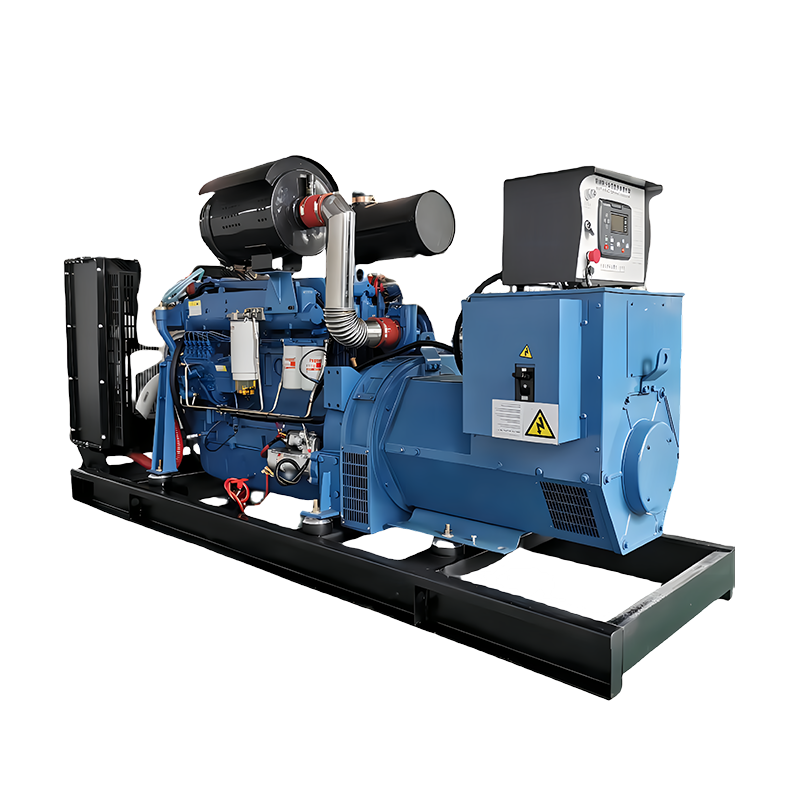

A mobile silent diesel generator set is an independent power supply device equipped with a silent box and a mobile chassis structure. It has the characteristics of low-noise operation, convenient mobility, and efficient power supply. It is widely used in outdoor construction, camping activities, emergency rescue, large-scale activities and other scenarios.

What is a mobile silent diesel generator set?

A mobile silent diesel generator set is an independent power supply device that integrates "power output, low noise, and portable structure". It is mainly composed of a diesel engine, a generator, a control system, a silent shell, and a mobile chassis. Its core advantage is that it does not rely on the power grid and can provide stable power supply for electrical equipment anytime and anywhere. It also reduces operating noise through engineering design, making it highly adaptable in the three major use scenarios that require "mobility, temporary, and quietness".

Compared with traditional diesel generators, the shell of the mobile silent unit uses thickened sound-absorbing cotton, composite noise reduction panels, and multi-stage silencer pipes to form an effective noise reduction barrier, so that the operating noise of the whole machine is controlled within 65~75 decibels, greatly reducing the interference to the working environment or surrounding residents.

The whole machine is installed on a frame with a traction device, mobile casters or a vehicle-mounted chassis at the bottom. It has high mobility and rapid deployment capabilities. It is particularly suitable for complex application scenarios such as engineering repairs, urban road operations, field construction, temporary activities, and power emergency support.

Working principle of mobile silent diesel generator set

The operation of mobile silent diesel generator set mainly depends on the following core systems to work together:

Power system (diesel engine):With high-efficiency diesel engine as the core power source, the engine outputs mechanical energy through the crankshaft to drive the generator to rotate. Diesel as a fuel has the advantages of high energy density, strong economy, stable power output, etc., and is particularly suitable for long-term and heavy-load operation.

Power generation system (AC generator):The generator converts the mechanical energy of the engine into AC power and achieves output voltage stability through the voltage regulator (AVR). According to user needs, single-phase or three-phase electricity can be output, supporting 50Hz/60Hz frequency.

Silent noise reduction system:This is an important feature of this type of product. The generator set is equipped with a fully enclosed silent box on the outside, covered with sound-absorbing cotton on the inside, and is designed with multi-level silencer ventilation ducts, anti-noise grid air outlets and silencer exhaust devices, which can effectively absorb engine running sound, exhaust sound and vibration sound, control the overall noise level, and ensure safety at night or in the city.

Control system:The control panel can monitor the operating data (voltage, current, frequency, speed, oil level, temperature, etc.) in real time, and has multiple safety functions such as overload protection, automatic alarm, oil shortage shutdown, overheating protection, and low-frequency protection. Some high-end models also support remote monitoring, mobile phone App control and modular parallel functions.

Mobile structure:The whole machine is equipped with wheels, lifting ears, tow hook interface or vehicle chassis, which is convenient for rapid towing, lifting and positioning by one person or vehicle. Some models are equipped with anti-slip feet and hydraulic shock-absorbing structure, which are more stable and reliable during transportation and operation.

Comprehensive upgrade of product matrix: 7 power ranges, full scene coverage

The mobile silent diesel generator sets, with their excellent silent performance, strong power output and highly convenient mobile structure, form a full-power product matrix covering 10kVA to 1500kVA, which widely meets the needs of multiple scenarios from personal outdoor electricity use to industrial-grade emergency support. The design of products in different power ranges fully considers the use environment and operational convenience, and has many technical advantages such as low-noise operation, rapid deployment, remote monitoring, and weather protection.

10<kVA≤100: Portable outdoor quiet power supply

The models in this power range are characterized by lightweight design and quiet effect, and are mainly used for:

Camping activities, power exhibitions, outdoor markets and other occasions: can provide stable power for lighting, audio, small appliances, etc., suitable for short-term power supply needs;

Small engineering sites and exploration operations: such as geological surveys, water conservancy inspections and other field operations that do not require high-power loads;

Emergency scene backup power supply: in the event of sudden power outages, it can provide backup power for small offices or important equipment.

Features include:

Compact structure, with portable handles and roller chassis, can be operated by one person;

Ultra-quiet design, can control the operating noise below 65dB, suitable for applications that require a quiet environment;

Equipped with a basic control panel and oil level alarm function to ensure safe use.

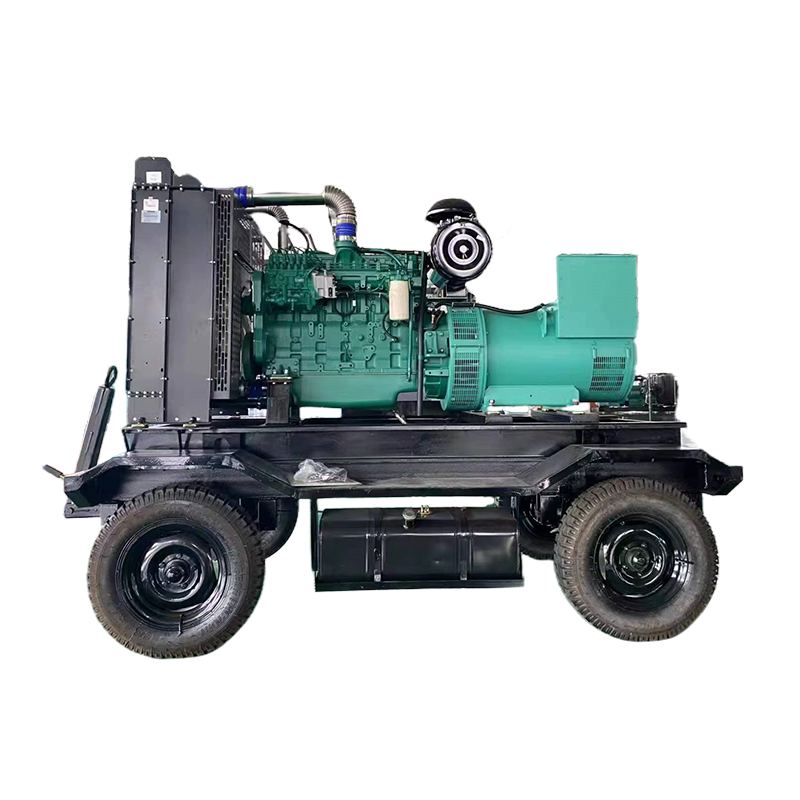

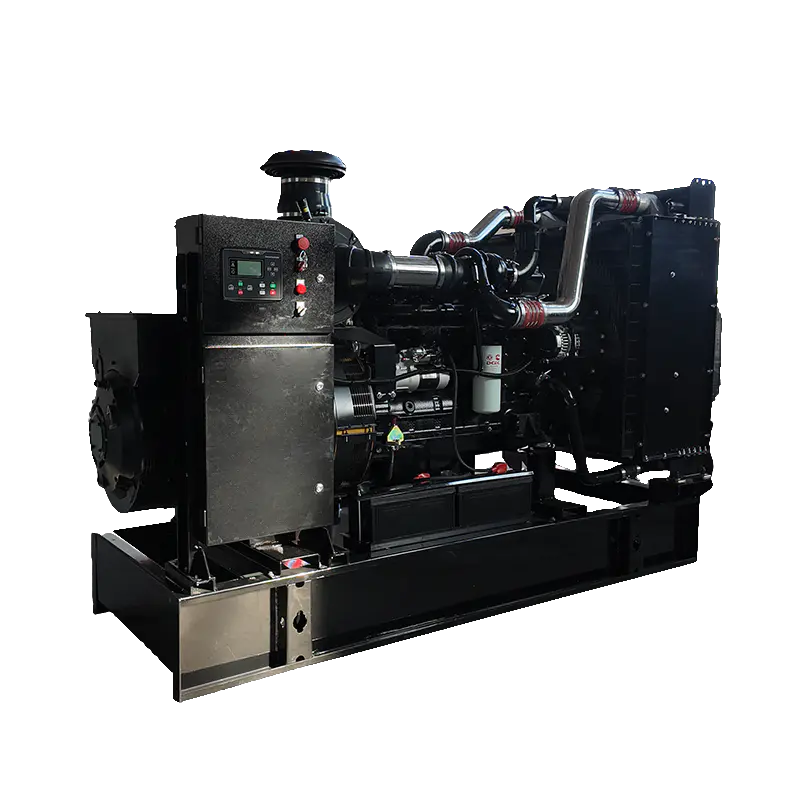

100<kVA≤300: A powerful tool for temporary power supply for small and medium-sized construction

The generator sets in this range are widely used in various temporary engineering operation scenarios, with good power output and mobility:

Suitable for the operation needs of medium-sized machinery: such as concrete mixers, welding equipment, small and medium-sized water pumps;

Municipal emergency power supply: such as power repair, sewer pipe reconstruction, temporary street light power supply, etc.;

Cooperate with the phased advancement of construction projects: support power supply rotation in different locations, and flexible on-site scheduling.

Technical highlights:

Mostly adopt trailer-type structure, with towing hook, shock-absorbing support and parking device;

The control system is upgraded, equipped with current, voltage, frequency monitoring table and automatic power-off protection;

Some models support rainproof and dustproof structural shell, which can adapt to moderately severe weather.

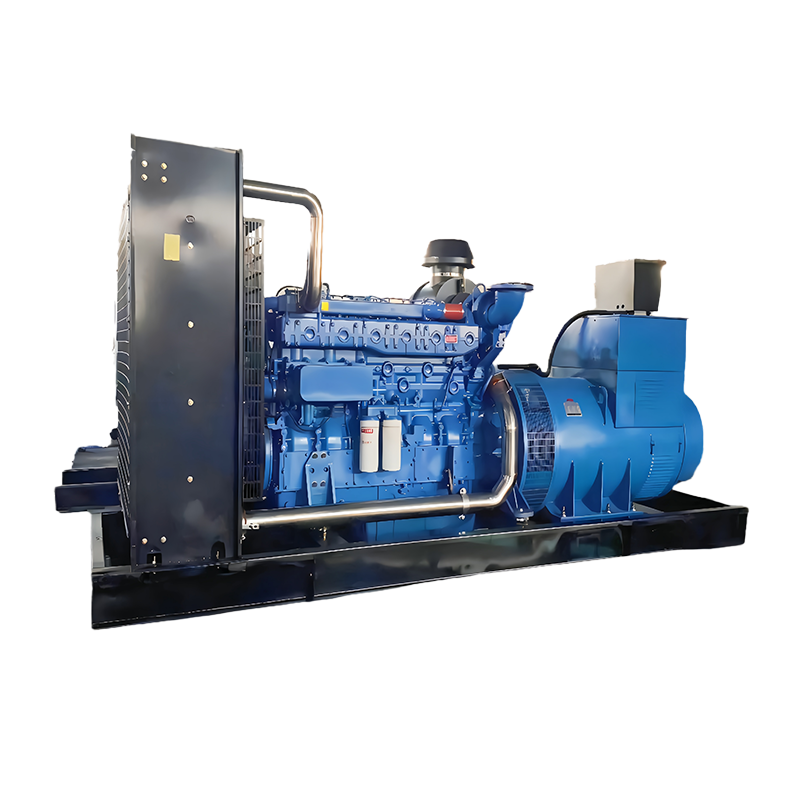

300<kVA≤500: Outdoor large-scale camping and engineering applications

This power range model belongs to medium and large portable power generation systems, suitable for scenarios that require long-term and high-stability power supply:

Field camp command, exploration station construction: such as oil exploration, hydrological stations, forestry field camps;

On-site multi-process parallel power supply: meet multiple needs such as lighting, office, communication, air conditioning, etc.;

Construction sites with environmental protection requirements: low-emission diesel engines, in line with National III or Euro V standards.

Features and advantages:

Equipped with a large-capacity fuel tank, supports 12~24 hours of continuous operation;

Adopts a fully enclosed silent cover + multi-layer sound-absorbing cotton structure to reduce environmental interference;

The output is stable, the fluctuation is controlled at ±1%, and multiple machines can be used in parallel.

500<kVA≤800: Multi-point power supply guarantee for industry and construction

This power range is positioned as the main power supply for heavy-load engineering sites, and is suitable for parallel operation of multiple loads:

Suitable for power supply of large construction sites, tower crane equipment drive, and continuous operation of mixing stations;

Suitable for power distribution in multiple areas, such as partitioned pouring and layered construction;

Temporary mobile power supply system for mining areas, pipe corridors, and long-distance bridge operation lines.

Product features:

Strengthened structure, chassis mostly adopts impact-resistant steel frame design;

The control system is equipped with digital display, remote start, overload alarm, and parallel interface;

Hydraulic shock absorption + hoisting structure, which can adapt to transportation and installation in complex terrain.

800<kVA≤1000: Dedicated for multi-functional high-load scenarios

It is a high-power silent power generation equipment, which is oriented to activity guarantee and multi-functional temporary power supply tasks:

Temporary power system for large-scale concerts, exhibitions, and sports events;

Municipal emergency repairs, rail transit tunnel construction, and night lighting projects;

Field hospitals, mobile command vehicles, and telecommunications base station support systems.

Features and highlights:

The silent hood enhances air circulation and heat management structure to avoid overheating;

The internal partition cooling system improves the continuous output capacity under high load;

The control system can be connected to the dispatching center to support remote diagnosis and maintenance.

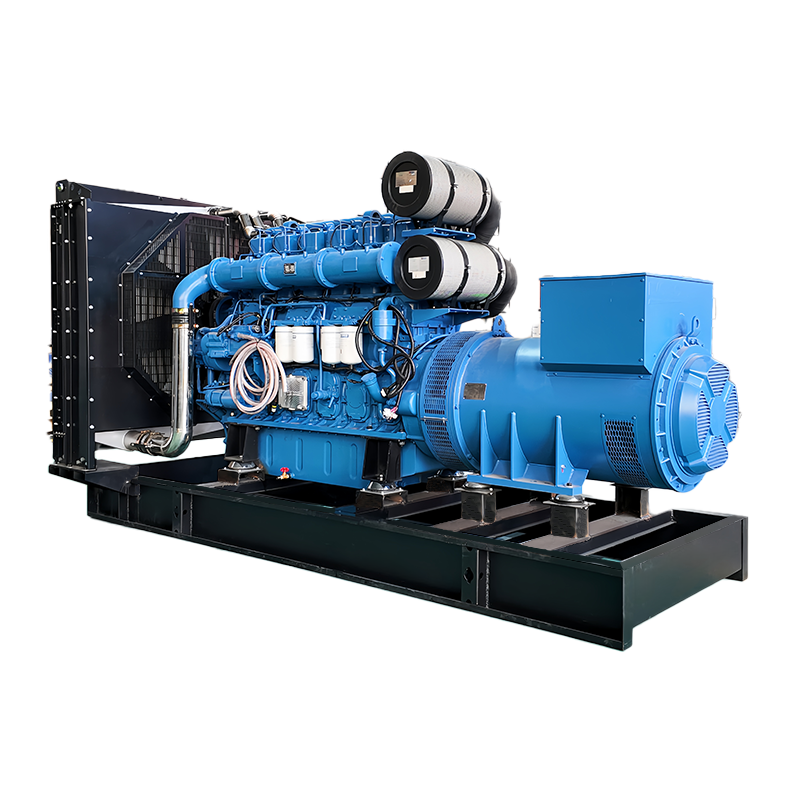

1000<kVA≤1200: First choice for emergency backup scenarios

This type of product is positioned as a backup power supply for key infrastructure and emergency response systems:

Hospitals, data centers, government agencies, rail transit dispatching systems, etc.;

Fire emergency systems in high-rise office buildings, elevator power supply backup;

Support all-weather emergency response to ensure that key equipment does not lose power.

Core advantages:

Short startup time (response within 10 seconds), with ATS automatic switching system;

Equipped with dual oil circuits and dual battery redundancy systems to improve stability;

Optional fuel level alarm and remote synchronous communication module for operating status.

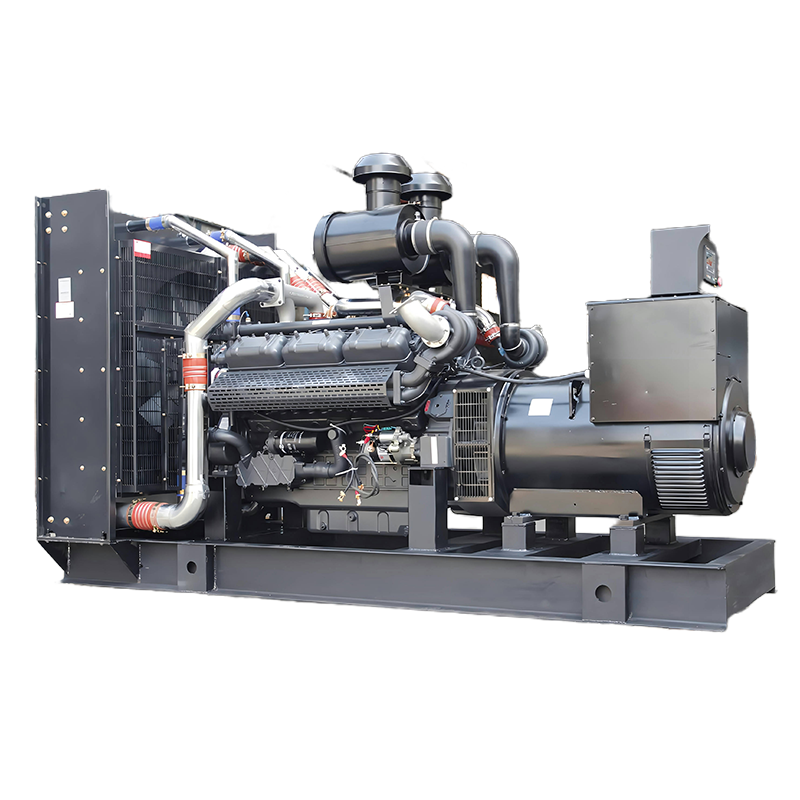

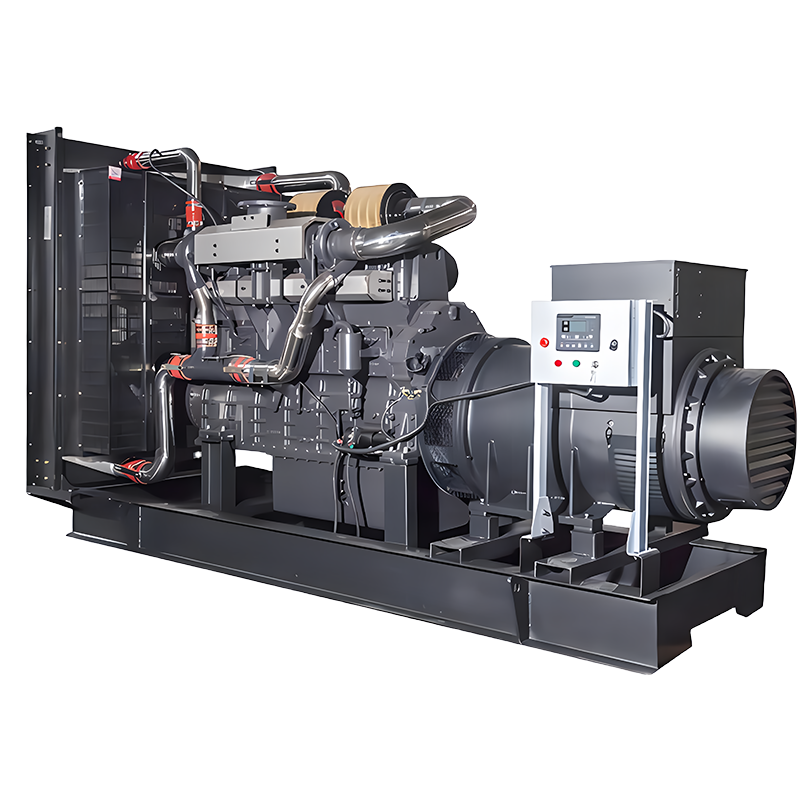

1200<kVA≤1500: Heavy-duty industrial and special demand solutions

This level of equipment is the flagship model of the entire series, and is used in scenarios with extremely high requirements for power supply capacity and operating stability:

Large mining plants, steel mills, military bases, petrochemical plants, etc.;

Temporary construction of large camps, logistics support command centers;

Backup power stations for city-level power grid operation and maintenance emergency response systems.

Top configuration:

Supports multi-parallel + load sharing mechanism, suitable for modular deployment;

Can be connected to the building energy management system (BEMS) to achieve automatic load adjustment;

Use high-performance noise reduction technology, automatic lubrication and heat dissipation system, continuous heavy-duty operation without chain failure.

Six advantages of mobile silent generators

As an important equipment for modern temporary power supply and emergency support, the mobile silent diesel generator set integrates a number of advanced technologies and humanized designs, and demonstrates excellent practicality and reliability in a variety of complex environments such as urban construction, field operations, emergency rescue, and public activities. This series of equipment not only supports multi-dimensional customization such as power, output standards, and control systems to meet the personalized needs of different industries and application scenarios; it also relies on its own manufacturing system to achieve efficient production and cost control and improve procurement efficiency. Its strict quality management system ensures that the equipment can operate stably in extreme environments such as high temperature, high humidity, and high dust. At the same time, it provides users with full-cycle technical support and operation and maintenance guarantees with a complete after-sales service network. More importantly, by optimizing the silent design, the noise pollution problem is effectively solved, so that it can also operate stably in noise-sensitive areas. It is widely used in multi-level power scenarios from camping power supplies to industrial heavy loads, and truly realizes the technical breakthrough and application value of "efficient power supply, silent and worry-free".

1. Support customization to meet the needs of different working conditions

Modern mobile silent generators have long surpassed the scope of "standard universal" power equipment, and have highly flexible customization capabilities to fully adapt to a variety of complex working conditions and global application needs. Its flexibility is first reflected in the wide coverage of the power range, from 10kVA small portable models to 1500kVA industrial-grade heavy-duty solutions, users can accurately select according to actual needs; secondly, the plug type and output port support customization according to different national and industry standards, ensuring barrier-free connection and application in multiple countries and complex construction sites; in terms of control systems, you can choose traditional mechanical button operation, or upgrade to an intelligent digital panel with integrated remote monitoring, automatic start and stop, operation data recording and other functions, greatly improving the convenience and intelligence of operation; in addition, the voltage and frequency standards are highly adapted, supporting switching between 50Hz and 60Hz systems, and can flexibly output 220V, 380V, 400V, 480V and other voltages to meet the requirements of different power grid systems around the world. This series of highly customizable features enables mobile silent generators to show excellent versatility and compatibility in construction, emergency rescue, power operation and maintenance, military deployment and large-scale events.

2. Own factories, greatly reducing procurement costs

Manufacturers of mobile silent generators with their own factories have shown advantages in reducing procurement costs and improving delivery efficiency. The company has full-process production capabilities from research and development, parts manufacturing to complete machine assembly, which greatly reduces the additional costs and delivery cycles caused by relying on middlemen and multi-level supply chains, and ensures the controllability and transparency of the production process; core components such as silent boxes, wiring harness systems, control modules, etc. are all produced by themselves, which can not only accurately control quality standards, but also effectively reduce the cost of raw material procurement and improve the overall cost performance; at the procurement and manufacturing level, through large-scale centralized procurement of core components and modular production and assembly processes, standardization and mass manufacturing are achieved, greatly reducing the manufacturing cost of a single device; for project-based customers or special scenario requirements, the factory has the ability to flexibly respond to small-batch customization, and can quickly adjust production parameters without relying on external supply, shortening delivery time and improving response speed. This vertically integrated production system not only achieves significant cost optimization, but also brings customers more competitive product prices and delivery guarantees.

3. Strict quality control to ensure stable and reliable equipment

High-performance mobile generators need to continuously output stable current during operation, so quality control is particularly critical. To ensure the reliability of the equipment, each generator must undergo rigorous whole-machine operation testing before leaving the factory, including key items such as full-load operation, voltage fluctuation response, current stability, and temperature rise control, to ensure stable performance under high-intensity usage scenarios. All core components such as engines, generator bodies, intelligent controllers, cable systems, and fuel modules are from high-quality suppliers that have passed industry certification and have source traceability. At the same time, the entire machine manufacturing process fully complies with the ISO9001 quality management system, and standardized and quantifiable testing processes have been established in all links. The generator set also has a high level of protection, which can cope with changing and complex operating environments such as dust, humidity, and high temperature, and effectively ensure the long-term stability of the equipment.

4. Strong production capacity to ensure delivery efficiency

With the help of automated testing platforms and load simulation systems, products can quickly complete full-item testing after assembly, ensuring stable quality while shortening delivery cycles. Some commonly used models will also be equipped with spot inventory or modular semi-finished product reserves to support rapid assembly and shipment on demand, which is particularly suitable for temporary and project-based order requirements. The overall production capacity can meet the monthly batch supply of thousands of units, and has the ability to undertake bulk orders and emergency responses at the same time. Through a strong production organization and delivery system, customers can obtain timely and reliable equipment guarantees in emergency application scenarios such as construction peaks, natural disasters, and power outages, greatly reducing the risk of project waiting and power outages.

5. More considerate after-sales service guarantee

To ensure the continuous and stable operation of the equipment and the long-term satisfaction of customers, modern mobile power generation equipment is usually equipped with a systematic after-sales support system. Service outlets or authorized partner networks are set up around the world to ensure timely supply of spare parts, convenient technical support, and efficient response to fault handling. In addition, some brands also provide regular inspections, remote monitoring and operation and maintenance service outsourcing options to effectively reduce the daily maintenance burden of customers. Through a complete after-sales service mechanism, not only the product experience is significantly improved, but also the life cycle and operation value of the whole machine are greatly extended.

6. Optimized silent design, ultimate operating experience

Silent technology is a core highlight of this mobile generator set, which is especially suitable for application scenarios with dense personnel, noise-sensitive or continuous operation at night. The whole machine box adopts a multi-layer composite silent structure design, with integrated sound-absorbing cotton, vibration isolation board and sealed noise reduction cabin inside, which effectively shields the propagation of mechanical noise; the intake and exhaust system uses frequency difference processing technology to effectively weaken the resonance sound caused by the fan and high-speed airflow; at the same time, the specially customized silencer system greatly suppresses the low-frequency roar generated when the engine is running. Through the synergistic effect of multiple noise reduction technologies, the operating noise of the whole machine at 7 meters is controlled below 65dB, which fully meets the use standards with high requirements for quiet environment such as urban construction, outdoor performances, and hospital backup power supply. The excellent silent capability not only significantly improves the working comfort of on-site operators, but also effectively avoids noise nuisance and complaints, and enhances the friendliness and compliance of the equipment in urban and public places.

Multi-scenario application, helping to ensure power supply in multiple industries

In the context of increasingly diversified and mobile electricity demand in modern society, mobile silent diesel generator sets have become key equipment for temporary power supply and emergency support in many industries with their core advantages such as flexible deployment, silent operation, and efficient output. Whether it is at a lively outdoor event site, emergency support for urban and rural power grids, high-load operations for infrastructure construction, or field projects in remote areas without city power, the equipment can provide stable, reliable and environmentally friendly power support. Through a multi-power product matrix and highly adaptable structural design, Greateagle mobile silent diesel generator sets are being widely used in cultural tourism, industry, transportation, energy and other fields, helping users to calmly cope with various complex power supply scenarios.

1. Power supply support for outdoor activities

As the frequency of large-scale outdoor events such as music festivals, marathons, trade fairs, film and television shooting, and RV camping festivals continues to rise, organizers often face practical problems such as remote venues, inaccessible municipal power grids, insufficient power facilities, or difficult connection during the organization process. Mobile silent diesel generator sets have become an important power solution to ensure the smooth progress of such activities with their advantages such as rapid deployment, high adaptability, and low noise.

The stable power output capacity can provide reliable power support for the entire venue, ensuring the stable operation of core facilities such as stage lighting, sound reinforcement systems, large screens, command centers, ticketing systems, and broadcasting equipment, and avoiding performance interruptions or service failures caused by unstable power supply. The generator set has the ability to provide continuous power supply around the clock, and can maintain equipment operation even in harsh weather to ensure that the event is not disturbed.

The ultra-quiet design using advanced noise reduction technology keeps the noise of the unit below 65 decibels during operation, effectively avoiding affecting the performance atmosphere or disrupting the audience experience. It is particularly suitable for night performances, city square activities, or use near residential areas, meeting the high requirements of public activities for environmental protection and comfort.

The flexible mobile structure design facilitates the rapid deployment of the unit to the site by towing or vehicle-mounted, achieving efficient support for cross-regional dispatching and multi-site patrol operations. Whether it is in the mountains, seaside, forest area or urban open space, it can be easily transported and quickly put into use, greatly reducing the restrictions on site selection and layout.

Supporting the parallel operation of multiple machines is the key guarantee for power supply for large-scale events. Through parallel technology, the total output power can be flexibly expanded according to actual load requirements, multi-region distributed power supply can be achieved, and the redundancy and stability of the system can be improved. When a certain device is maintained or fails suddenly, other parallel units can automatically bear the load to ensure uninterrupted power supply and ensure the safety and smooth progress of the event.

2. Emergency backup of urban and rural power grids

The stability of power supply is crucial in urban operations and rural production. Sudden power outages will not only seriously affect residents' daily lives, but may also lead to a series of chain reactions such as business shutdowns, traffic signal interruptions, and medical treatment obstructions. Therefore, as an important part of the power grid emergency backup system, mobile silent diesel generator sets have become an effective solution to ensure the safety of power use in key scenarios with their rapid response capability and high adaptability.

The equipment has a fast start-up response capability. When a power grid power outage signal is detected, the unit with a self-starting function can automatically start and connect to the load within a few seconds, quickly restore power supply, and avoid the loss of important data or shutdown of key equipment due to power outages. Some models are also equipped with a remote start function, which supports remote control operations in remote duty or unmanned places to improve emergency response efficiency.

The generator set can provide stable support for critical loads. In units such as hospitals, schools, communication base stations, and water plants that have extremely high requirements for power supply stability, mobile silent generators can ensure the continuous operation of life support systems, teaching facilities, communication networks, and water treatment equipment, effectively prevent safety hazards or service interruptions caused by power outages, and maintain the basic operation order of society.

In rural areas, the problems of weak grid coverage and long maintenance response time are more prominent. Mobile generators are highly adaptable to remote rural areas and can be quickly deployed to disaster-stricken villages, agricultural facilities, livestock and poultry farms and other places where electricity is urgently needed, providing stable temporary power support for rural residents' lives, agricultural irrigation, livestock heating, etc., and making up for the shortcomings of slow recovery of local power systems.

The supporting intelligent monitoring platform improves management and operation and maintenance efficiency. The platform can realize remote monitoring and early warning of key parameters such as unit operating status, power output, fuel remaining, maintenance cycle, etc. Managers can view equipment data in real time through mobile phones or computers, plan maintenance plans in advance, ensure efficient and economical operation of equipment, and further promote the digitalization and intelligent upgrading of power supply systems.

3. Power supply for infrastructure and large construction sites

In large-scale construction projects such as subway construction, building construction, bridges and tunnels, and municipal renovation, the on-site power load is usually high and changes frequently, and the work site is often located in an area far away from the mains access point, which puts higher requirements on the stability, flexibility, and continuous output capacity of the power supply equipment. With its excellent adaptability and operating performance, the mobile silent diesel generator set has become an ideal power supply solution for high-intensity construction scenarios.

The equipment provides a variety of power range options, ranging from 100kVA to 1500kVA, and can be flexibly configured according to the load requirements of different construction stages of the project. Whether it is the light load of initial earthwork excavation or the high-intensity power consumption of later mechanical intensive construction, it can be accurately matched to effectively avoid energy waste or insufficient load and improve overall construction efficiency.

It supports parallel operation of multiple units, and can connect several power generation equipment to the same power network for operation, realizing power superposition and redundant backup, which is suitable for the needs of power supply for multiple work surfaces or regional power supply at large construction sites. It not only improves the power supply capacity, but also ensures that power is not interrupted when a single device is maintained or fails, ensuring that the construction progress is not disturbed.

The generator set has the ability to operate around the clock. The whole machine structure adopts industrial-grade protection design such as high temperature resistance, wind and sand resistance, rain and snow resistance, etc., which can stably cope with the common harsh climate and complex terrain conditions on the construction site. Whether it is working under the scorching sun in summer or in the windy and snowy winter, the equipment can maintain continuous and stable power output.

4. Field construction and power supply in remote areas

In the construction of field communication base stations, power transmission line inspections, geological exploration, water conservancy pipeline laying and other operations, since they often go deep into remote areas such as mountainous areas, forests, and deserts, these areas generally have problems such as lack of city power coverage, lack of power supply facilities, and long construction periods. Traditional power supply methods are inconvenient to carry or insufficient power generation capacity, and are difficult to be competent for continuous power supply tasks. Mobile silent diesel generator sets have become an indispensable and reliable power guarantee in field operations with their high adaptability and stable performance.

Its highly adaptable structural design fully considers the transportation needs of complex terrain. The equipment adopts an off-road wheeled chassis and a reinforced traction structure. It not only has good passability, but can cope with harsh road conditions such as mountains, muddy roads, and gravel ramps. It also supports a variety of transportation methods (such as towing or truck loading), ensuring that the power generation equipment can be quickly deployed to the field construction site, effectively shortening the pre-preparation time.

Equipped with a large-capacity fuel tank design, it can continuously and stably output power for more than dozens of hours, meeting the power supply needs of long-term duty and continuous operation. For areas without electricity where there are few people and it is difficult to supply, long endurance is particularly important, which reduces the material consumption and personnel deployment pressure caused by frequent refueling, and improves the operation efficiency and continuity of project execution.

The equipment adopts a high-protection shell structure, which has excellent rain, dust and corrosion resistance, and can operate stably under severe outdoor weather conditions such as wind, sand, high humidity and strong ultraviolet rays. The closed silent box combined with weather-resistant materials and sealing design not only extends the service life of the equipment, but also ensures the working reliability of core components in extreme environments.

The generator set can also be used as a "mobile energy vehicle" modification platform to provide supporting power solutions for various special vehicles. For example, it provides continuous power supply for on-site command vehicles, communication vehicles, camping vehicles, medical vehicles, etc., to ensure the diversified power needs of frontline operators such as office, communication, and life, and create an efficient "mobile power supply operation system", which greatly improves emergency deployment and remote operation capabilities.

Environmental protection and energy saving: coexistence of low emissions and high fuel efficiency

As an important carrier of temporary power supply and emergency power supply, the mobile silent diesel generator set not only plays an irreplaceable role in various key scenarios, but also continuously breaks through the performance boundaries of traditional equipment in technological innovation. It integrates a number of cutting-edge technologies such as modern power engineering, environmental protection engineering and acoustic control, fully reflecting the high pursuit of "low emissions and high fuel efficiency". From the optimization of engine combustion efficiency, to the upgrade of exhaust emission control system, to the introduction of intelligent management and energy-saving mode, the whole system effectively reduces the impact on the environment while maintaining strong and stable output. Through the integration and iteration of this series of collaborative technologies, the mobile silent diesel generator set has achieved an organic balance between power supply performance and green environmental protection, and gradually moved towards a new generation of efficient, energy-saving and intelligent power equipment, providing a solid and reliable energy guarantee for sustainable development on a global scale.

1.Low fuel consumption diesel engine, in compliance with mainstream environmental regulations

Currently, most high-performance mobile diesel generator sets are equipped with low-emission engines, strictly complying with mainstream environmental regulations such as EU Stage V, China National III, and US EPA Tier 4. This type of power system effectively reduces the generation of combustion residues by optimizing the combustion chamber structure, and integrates DOC catalyst, DPF particulate filter and SCR urea reduction system in the exhaust system to achieve multiple purification of harmful emissions such as nitrogen oxides (NOx), hydrocarbons (HC) and particulate matter (PM), greatly reducing the risk of air pollution from source to end, and significantly improving the environmental performance of the equipment.

2. High-efficiency combustion system to improve energy utilization

By adopting electronically controlled high-pressure common rail injection system and turbocharger + intercooler intake technology, modern mobile diesel generator sets have achieved significant improvements in combustion efficiency and energy consumption control. The high-pressure common rail system can accurately control the injection amount and injection timing according to real-time load and environmental conditions, so that the fuel is more fully atomized and burned more completely, thereby significantly reducing fuel consumption and harmful emissions. The synergy of the turbocharger and the intercooler system greatly increases the intake density and air oxygen content, making the combustion more explosive and stable, especially under high load and continuous operation conditions.

This technical combination not only effectively improves the fuel utilization rate under unit power, improves the power response and power generation stability of the whole machine, but also avoids the energy waste and heat load accumulation caused by inefficient combustion, which helps to extend the service life of the equipment. For scenes that require long-term and continuous operation, such as field construction, emergency power supply, and temporary large-scale activities, this energy-saving and efficient power configuration undoubtedly greatly reduces operating costs, improves the overall power guarantee capability, and brings users a more economical, environmentally friendly and reliable energy solution.

3. Large fuel tank and long endurance, reduce operating frequency

In order to meet the needs of long-term continuous power supply for field operations, emergency rescue and unmanned operation, modern mobile silent diesel generator sets are generally equipped with large-capacity fuel tank systems, supplemented by intelligent fuel-saving operation modes. This type of design supports equipment to run continuously for 20 hours or even longer without refueling, greatly reducing the interruption risk and manpower investment costs caused by frequent refueling. This high endurance feature is particularly critical in remote areas or environments with difficult power access, which not only improves the efficiency of task completion, but also significantly enhances the flexibility of energy scheduling.

Long-term and efficient operation reduces fuel consumption fluctuations and mechanical wear caused by frequent start-stop of equipment, effectively extending the service life of the whole machine. In terms of energy saving, by optimizing injection control and automatic load adjustment technology, the engine is always kept in the optimal energy efficiency range, minimizing fuel consumption and carbon emissions. This technical strategy that integrates "high endurance, low energy consumption, and low maintenance" has become an important development direction for current high-performance mobile power equipment.

4. Intelligent control system, precise adjustment of load and fuel consumption

Modern mobile power generation equipment is generally equipped with an intelligent control unit (ECU) or a digital display control panel, which can monitor power load changes in real time and automatically adjust the engine speed and output power to achieve efficient operation and energy-saving control. When the equipment is in a low-load state, the system will automatically switch to idle operation to avoid fuel waste caused by ineffective idling of the engine at high speed. In addition, some models support ECO energy-saving mode, which further reduces fuel consumption and extends operating time under light-load conditions. For scenarios where multiple machines are running in parallel, the intelligent control system can also achieve dynamic load balance distribution, effectively avoid single machine overload or idleness, and comprehensively improve overall energy efficiency and operation stability.

5. Green life cycle from manufacturing to recycling

Mobile silent diesel generator sets generally use low-emission diesel engines that meet international mainstream environmental emission standards such as EU Stage V, China National III or US EPA Tier 4, significantly reducing the emission of nitrogen oxides (NOx), hydrocarbons (HC) and particulate matter (PM), effectively reducing air pollution.

The internal structure of the unit is constantly optimized. For example, the combustion chamber design has been precisely calculated to improve combustion efficiency and reduce unburned residues; the exhaust system integrates multiple purification components, such as DOC oxidation catalyst, DPF particulate filter, SCR selective catalytic reduction device, etc., which work together to greatly purify exhaust gas and reduce carbon footprint. In addition, many models also introduce intelligent fuel-saving systems to automatically adjust the fuel injection amount and engine speed according to load changes, achieve low fuel consumption under low load, and improve fuel utilization.

In order to extend the operating time and reduce operating costs, this type of power generation equipment is generally equipped with a large-capacity fuel tank. Combined with intelligent control technology, it can achieve continuous operation for more than 20 hours with a single refueling, meeting the long-term use needs of field construction, emergency power supply, etc. At the same time, long-term stable operation can reduce the frequency of start-stop, reduce mechanical wear, and improve overall energy efficiency.

From design to use, this type of generator set reflects the deep integration of the green operation concept, which not only ensures the reliability of power supply, but also takes into account energy saving and consumption reduction and environmental friendliness, providing a reliable energy solution for the green transformation of multiple industries.

English

English Español

Español عربى

عربى