Industrial Generators Drive Efficiency in Construction and Mining Operations

Dec 17, 2025

Content

- 1 Understanding Industrial Generators

- 2 Key Advantages for Construction Operations

- 3 Applications in Mining Operations

- 4 Technological Features Enhancing Efficiency

- 5 Maintenance and Operational Considerations

- 6 Market Trends and Industry Outlook

- 7 Case Studies in Construction and Mining

- 8 Future Prospects

Reliable power is a fundamental requirement in construction and mining operations. Projects in these sectors often take place in remote or off-grid locations where consistent electricity is not available. In such scenarios, industrial generators play a crucial role by providing uninterrupted power to machinery, lighting, and support systems. By ensuring continuous operations, industrial generators help companies maintain productivity, meet project deadlines, and reduce downtime.

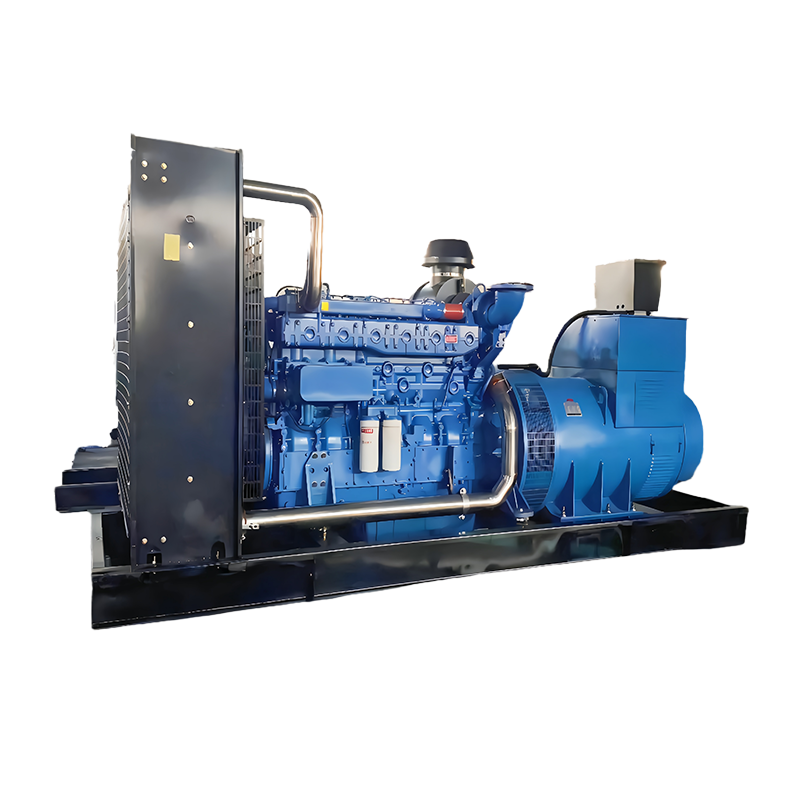

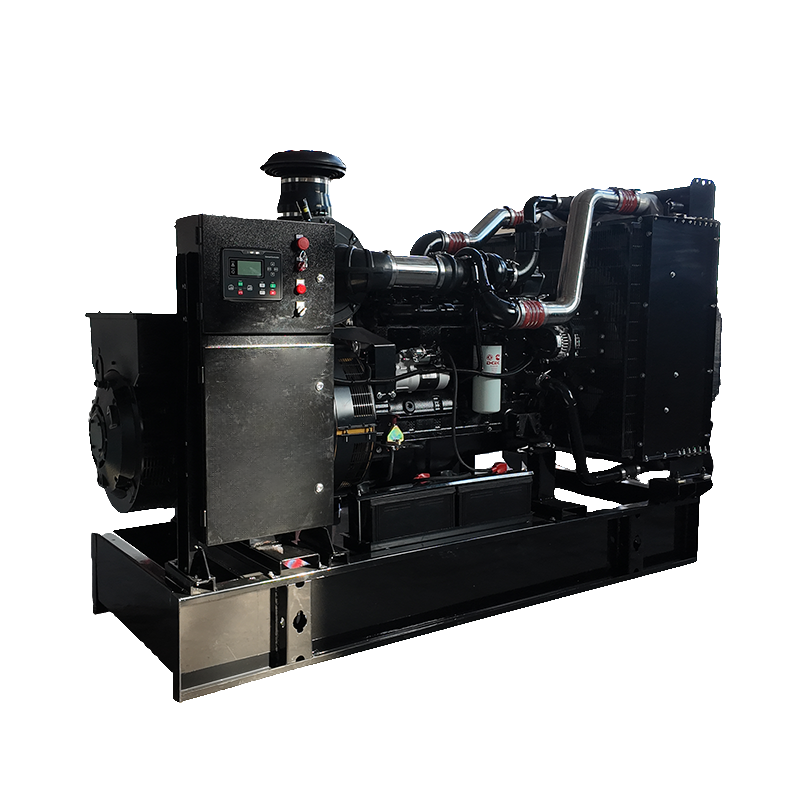

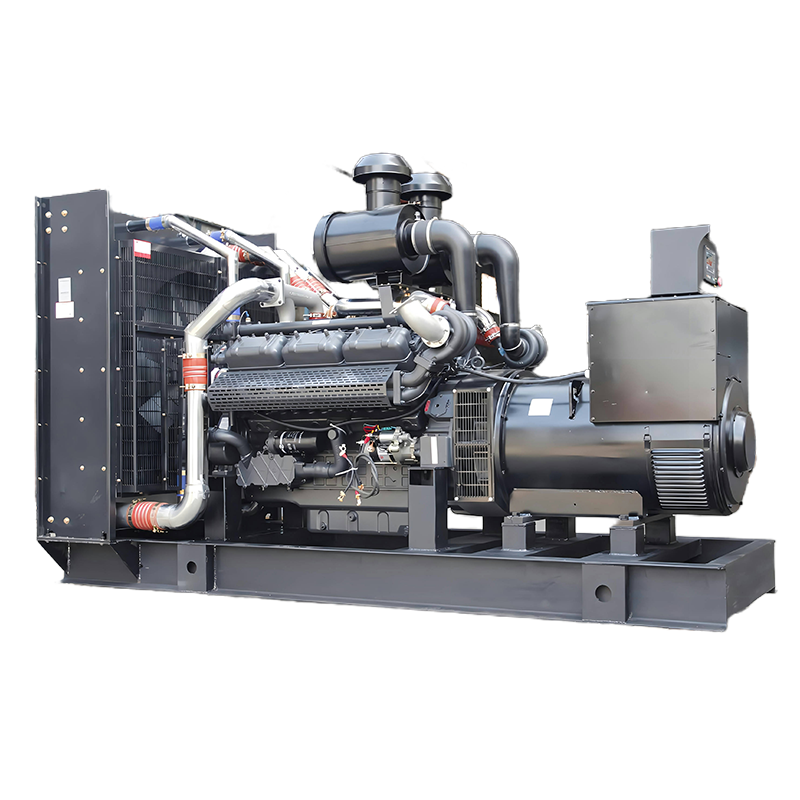

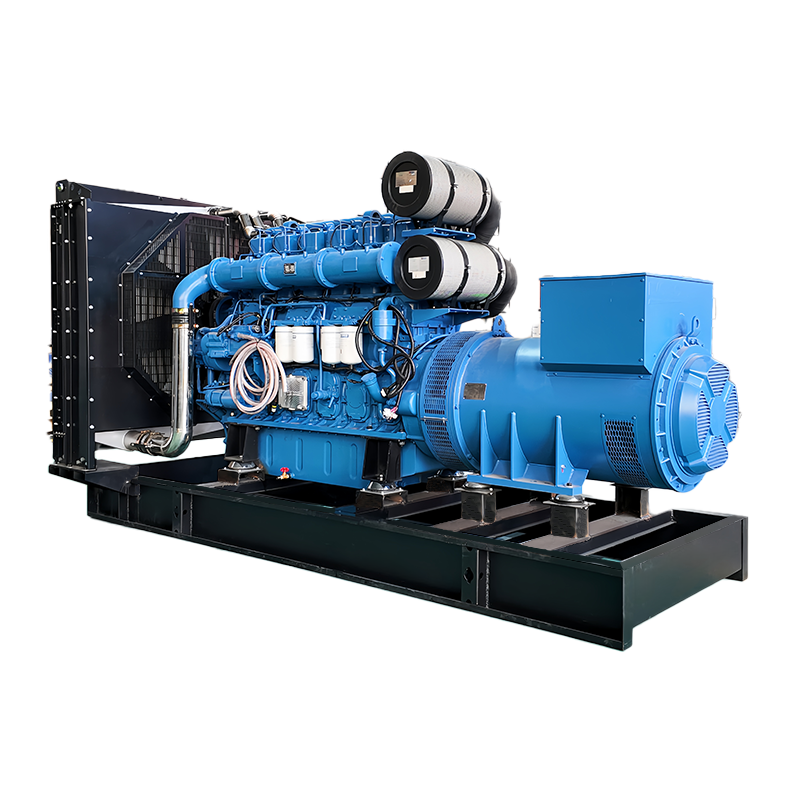

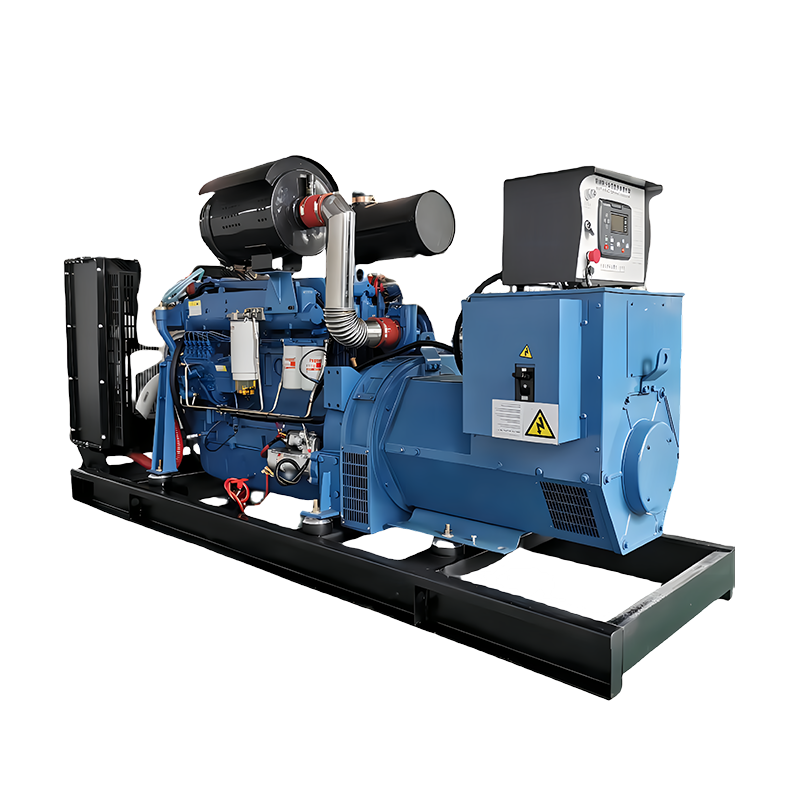

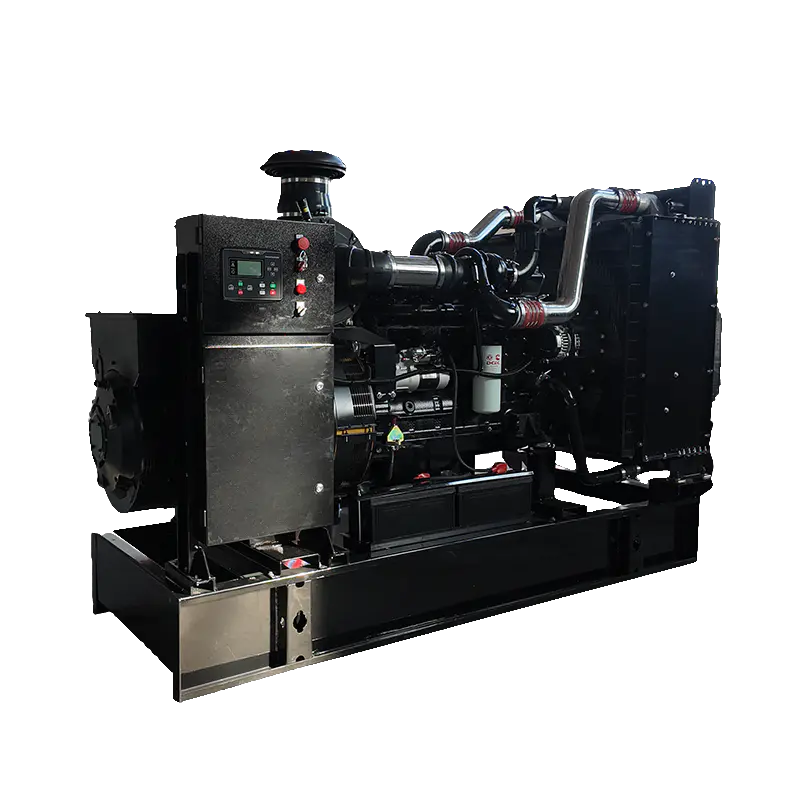

Understanding Industrial Generators

An industrial generator is a heavy-duty power generation system designed to provide reliable electricity in commercial and industrial settings. These generators are built to withstand demanding conditions, operate for extended hours, and handle high electrical loads. Industrial generators can be powered by diesel, natural gas, or hybrid fuel systems, depending on operational needs and environmental considerations.

Unlike smaller generators, industrial models are engineered for continuous operation and can support critical equipment such as excavators, drills, conveyor belts, lighting systems, and control panels. Many modern generators also include features such as automatic transfer switches, remote monitoring, and voltage stabilization to optimize performance and protect connected equipment.

Key Advantages for Construction Operations

Construction projects rely heavily on timely and efficient power supply for multiple activities, including earthmoving, concrete mixing, and temporary site lighting. Industrial generators improve efficiency in these environments through several key advantages:

Reliable Power Supply

Construction sites often operate in areas without direct access to the electrical grid. Industrial generators provide a dependable source of electricity, ensuring that essential machinery and tools function without interruption. Consistent power prevents delays and keeps projects on schedule.

High Load Capacity

Heavy machinery, such as cranes, cement mixers, and pumps, requires significant electrical power. Industrial generators are designed to handle large loads, distributing electricity efficiently to multiple devices simultaneously. This reduces the need for multiple smaller generators and simplifies site logistics.

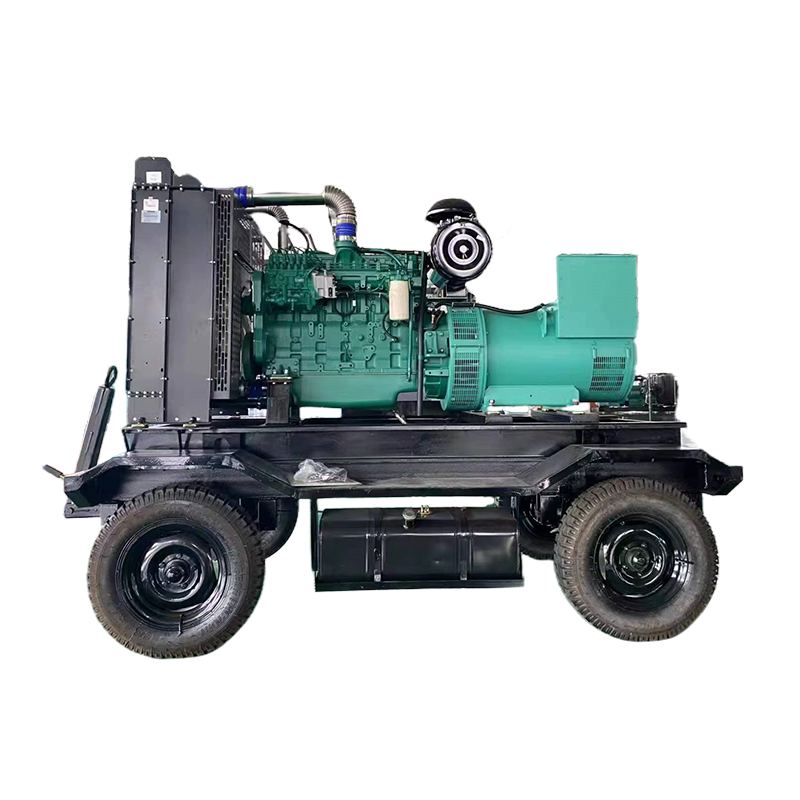

Flexibility and Mobility

Many construction projects require temporary power in different locations. Portable industrial generators can be transported easily across sites, allowing operators to relocate power sources as needed. Stationary models provide long-term power solutions for larger, fixed projects. This combination of mobility and capacity improves operational flexibility.

Energy Efficiency

Modern industrial generators are designed with energy efficiency in mind. Advanced fuel injection systems, load optimization, and hybrid configurations reduce fuel consumption while maintaining consistent power output. Efficient energy use lowers operational costs and contributes to sustainable practices in construction.

Enhanced Safety

Power interruptions on construction sites can create safety hazards. Industrial generators provide a steady power supply for safety equipment such as lighting, ventilation, and communication systems. Automated voltage regulation and protective features further prevent equipment damage and maintain a secure working environment.

Applications in Mining Operations

Mining operations, often located in remote regions with limited infrastructure, rely heavily on industrial generators for continuous power. Reliable electricity is essential for drilling, crushing, conveyor systems, ventilation, and lighting. Industrial generators enable mining companies to operate efficiently and safely under challenging conditions.

Continuous Mining Operations

Mining projects often operate around the clock to maximize output. Industrial generators ensure uninterrupted power supply, supporting continuous drilling, extraction, and material handling. This reliability allows mining companies to achieve production targets while minimizing operational downtime.

Remote Site Support

Many mines are situated far from urban centers, making grid electricity unavailable. Industrial generators provide a standalone power solution, capable of operating in harsh environmental conditions. Diesel and natural gas generators are particularly suited for such remote applications due to their durability and fuel availability.

Integration with Heavy Machinery

Mining equipment, such as conveyor belts, crushers, and hoists, requires stable and consistent power. Industrial generators provide the necessary voltage stability and load handling capacity, ensuring smooth operation and reducing the risk of mechanical failures caused by power fluctuations.

Environmental and Safety Compliance

Modern industrial generators are designed to meet emission standards and safety regulations, making them suitable for environmentally sensitive mining operations. Properly maintained generators reduce harmful emissions, supporting sustainability initiatives while ensuring worker safety.

Technological Features Enhancing Efficiency

Several technological advancements have made industrial generators more efficient and reliable for construction and mining applications:

- Automatic Transfer Switches (ATS): Enable seamless transition between grid power and generator supply, reducing downtime during outages.

- Remote Monitoring Systems: Allow operators to track generator performance, fuel levels, and maintenance needs from a centralized location.

- Voltage Regulation and Load Balancing: Ensure stable electricity supply to sensitive machinery, preventing equipment damage.

- Fuel-Efficient Engines: Advanced diesel or gas engines improve energy efficiency and reduce operational costs.

- Hybrid Systems: Integration of renewable energy sources, such as solar panels or battery storage, with generators reduces fuel consumption and environmental impact.

These features enhance the reliability, safety, and efficiency of industrial generators, allowing construction and mining projects to maintain consistent operations.

Maintenance and Operational Considerations

Regular maintenance is essential to maximize the lifespan and efficiency of industrial generators. Key maintenance practices include:

- Scheduled Inspections: Routine checks of engine components, fuel systems, and electrical connections prevent unexpected failures.

- Fuel Management: Monitoring fuel quality and storage conditions reduces the risk of contamination and operational interruptions.

- Load Testing: Periodic testing ensures the generator can handle the required power load without performance issues.

- Cooling and Ventilation Maintenance: Proper airflow and cooling systems prevent overheating and extend engine life.

- Operator Training: Skilled operators can optimize generator performance, troubleshoot issues, and ensure safe operation.

Proper maintenance reduces downtime, improves efficiency, and extends the service life of industrial generators.

Market Trends and Industry Outlook

The industrial generator market is evolving in response to technological advancements, regulatory requirements, and operational demands:

- Demand for High-Capacity Generators: Large-scale construction and mining projects require generators with higher output and load handling capabilities.

- Integration with Smart Systems: Remote monitoring and predictive maintenance technologies are becoming standard features, enabling operators to optimize generator performance.

- Fuel Efficiency and Sustainability: Diesel and gas generators with improved fuel efficiency and lower emissions support environmentally responsible practices.

- Portable and Modular Designs: The need for flexible, easily transportable power solutions is driving the development of modular and mobile generators.

- Hybrid and Renewable Integration: Combining industrial generators with solar panels or battery storage provides reliable, cleaner energy solutions for remote sites.

These trends indicate that industrial generators will continue to be a vital component of construction and mining operations, offering reliability, efficiency, and adaptability.

Case Studies in Construction and Mining

Several real-world examples demonstrate how industrial generators enhance efficiency:

- Construction Sites: Large infrastructure projects have reported reduced downtime and improved productivity after deploying high-capacity generators to power cranes, mixers, and temporary lighting.

- Remote Mining Operations: Mines in isolated regions have maintained continuous extraction and processing schedules by using diesel generators with fuel optimization systems.

- Hybrid Installations: Some mining companies have integrated solar panels with industrial generators, achieving fuel savings while maintaining reliable power for critical equipment.

These examples highlight the practical benefits of industrial generators in maintaining operational efficiency and reducing costs.

Future Prospects

As construction and mining industries continue to expand globally, the demand for reliable, efficient, and adaptable power solutions will grow. Industrial generators will play an increasingly important role in supporting large-scale projects, remote operations, and environmentally responsible practices.

Emerging technologies, such as hybrid systems, remote monitoring, and predictive maintenance, will further enhance generator performance and reduce operational risks. Manufacturers are likely to develop generators with higher efficiency, lower emissions, and improved integration with smart systems, meeting the evolving needs of the construction and mining sectors.

English

English Español

Español عربى

عربى