The Ultimate Guide to Diesel Generators: Powering Your Life and Business

Aug 22, 2025

Content

Introduction to Diesel Generators

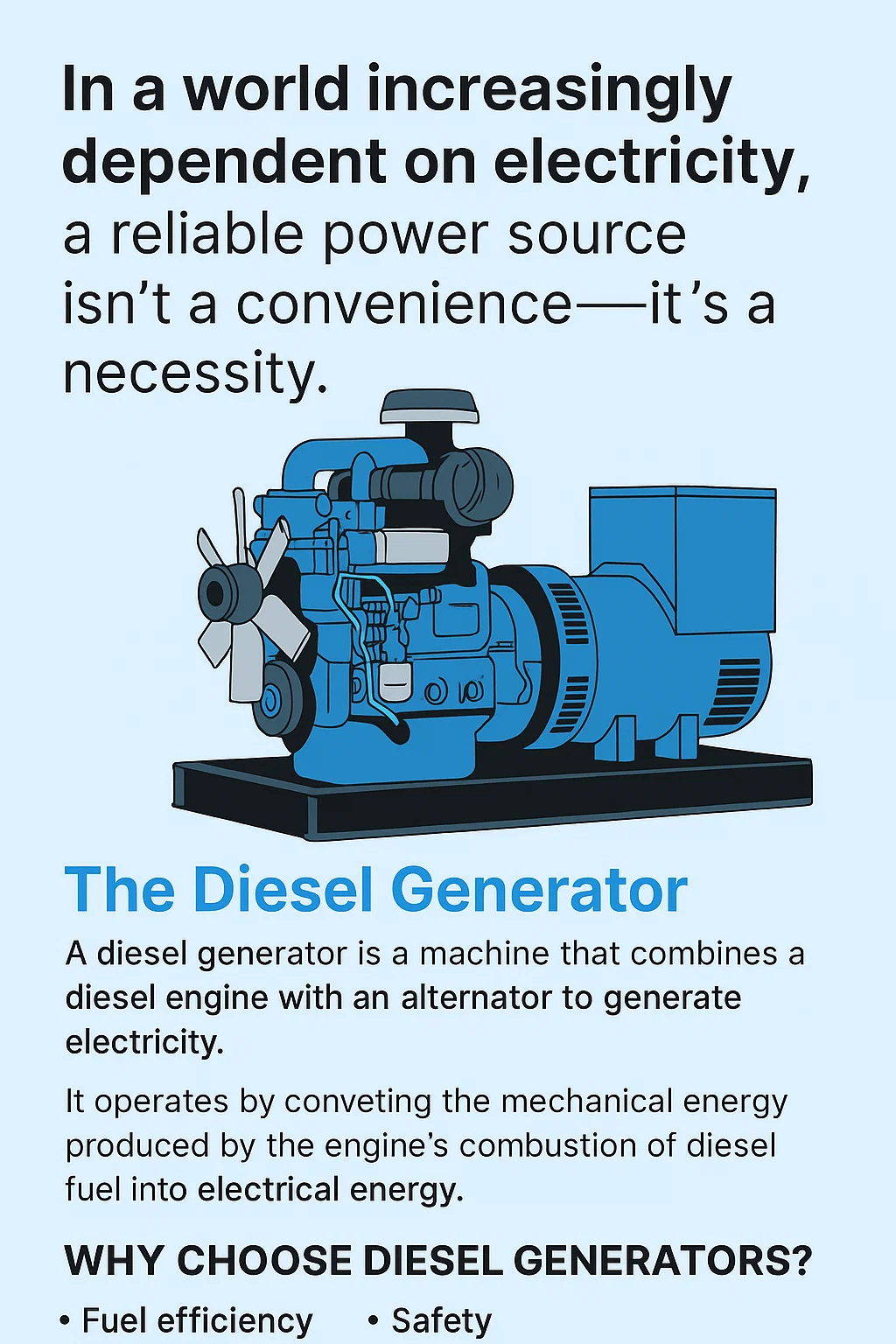

In a world increasingly dependent on electricity, a reliable power source is not just a convenience—it's a necessity. Whether it's to keep the lights on during a storm, power critical medical equipment, or maintain operations in a large-scale industrial plant, the need for uninterrupted electricity is paramount. This is where the diesel generator comes in, standing as a cornerstone of dependable backup and primary power solutions across the globe.

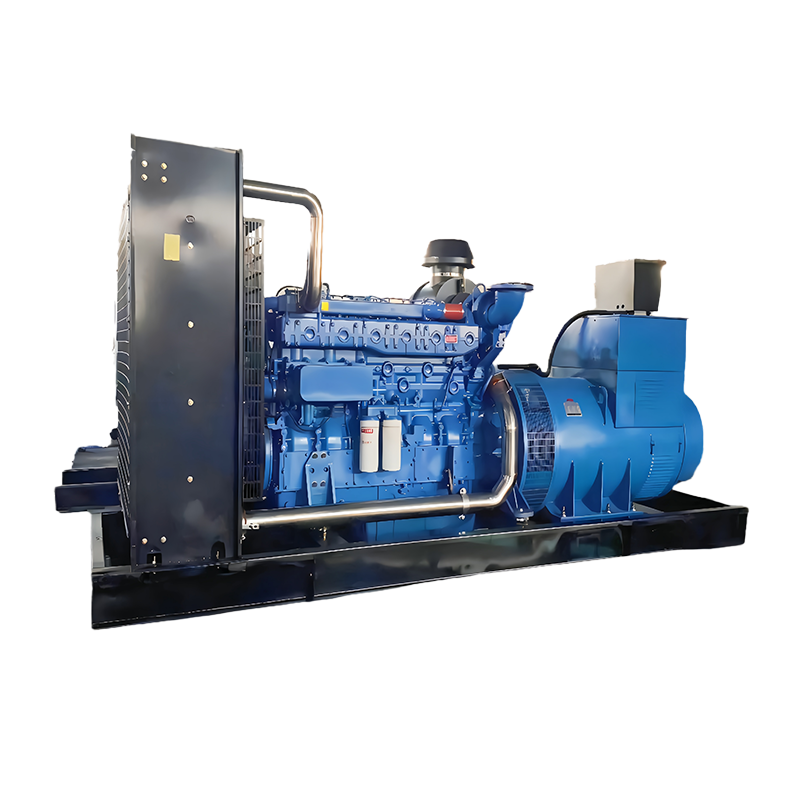

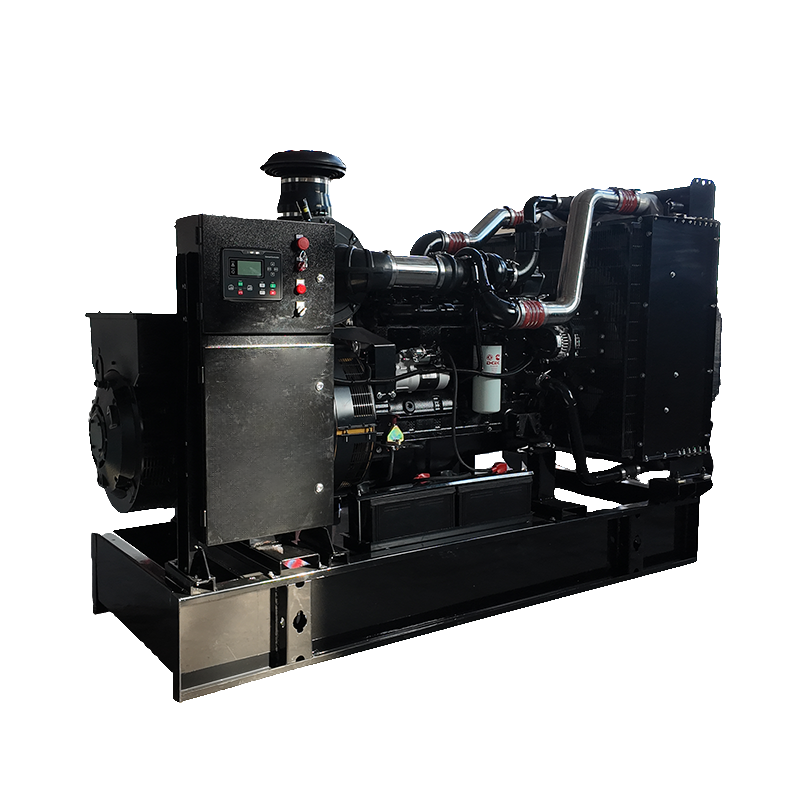

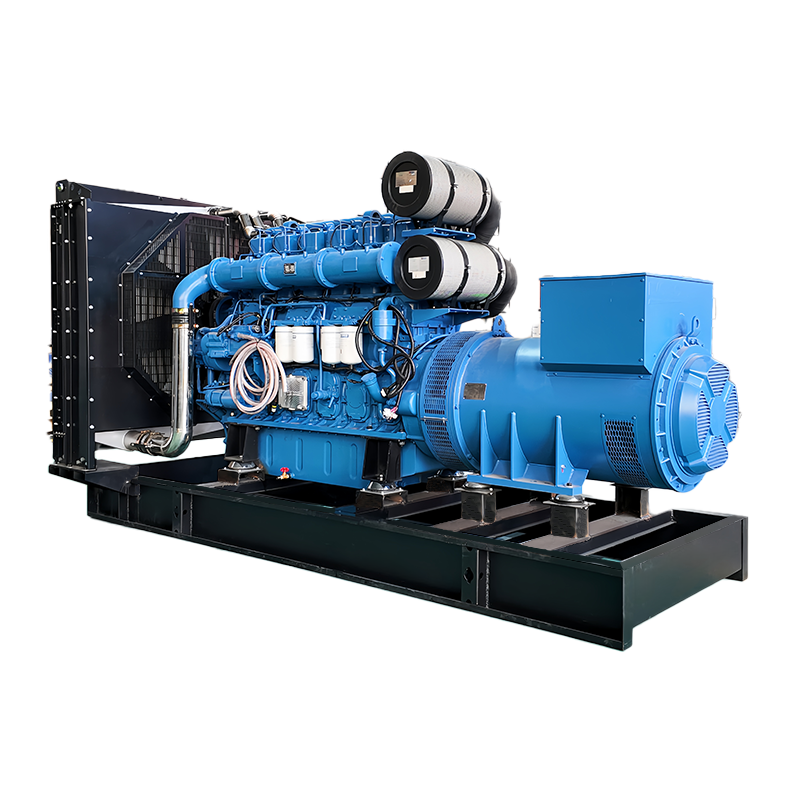

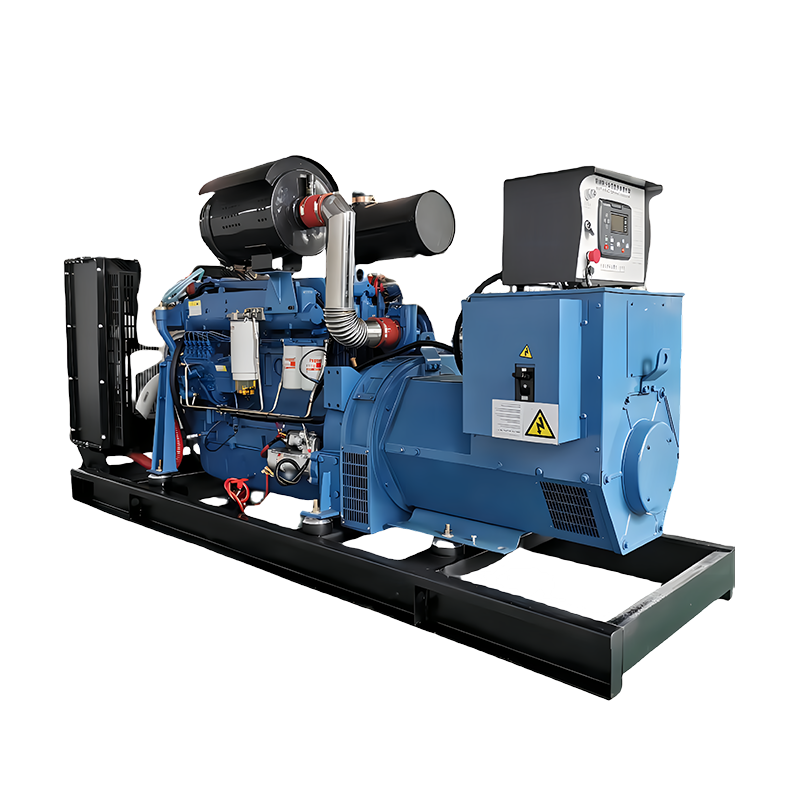

A diesel generator, or power generator, is a machine that combines a diesel engine with an alternator to generate electricity. It operates by converting the mechanical energy produced by the engine's combustion of diesel fuel into electrical energy. These powerful machines are renowned for their durability, fuel efficiency, and long lifespan, making them a preferred choice for a wide range of applications, from residential backup to powering entire cities.

The history of the diesel generator is tied directly to the invention of the diesel engine by Rudolf Diesel in 1892. Originally conceived to run on various fuels, including vegetable oil, the engine's design was refined over the years. By the early 20th century, engineers began pairing these robust engines with electrical generators, creating the first practical diesel-electric power systems. These early models were large and primarily used for industrial and marine applications. Over time, advancements in technology have led to smaller, more efficient, and quieter models, making them accessible for commercial and residential use.

So, why choose diesel generators over other types of generators, such as those that run on gasoline or propane? The primary reasons are fuel efficiency, safety, and longevity. diesel generator can run for longer on the same amount of fuel, which is crucial during extended power outages. Additionally, diesel is a less flammable fuel than gasoline, reducing the risk of fire. The robust design of diesel engines also means they can withstand heavy use and typically have a much longer operational life than their gasoline counterparts, making them a wise long-term investment.

How Diesel Generators Work

At its core, a diesel generator is a marvel of mechanical and electrical engineering, designed to seamlessly transform chemical energy into usable electricity. Understanding its inner workings provides insight into why these machines are so efficient and reliable.

The heart of the generator system is the diesel engine, a type of internal combustion engine that operates on the compression-ignition principle. The process begins when the engine's piston moves down, drawing in clean air. As the piston rises, it compresses this air to an incredibly high pressure. This intense compression raises the temperature of the air to several hundred degrees—hot enough to ignite diesel fuel without a spark plug. At the peak of compression, a fuel injector atomizes a precise amount of diesel into the cylinder. The finely misted fuel instantly ignites upon contact with the superheated air, creating a powerful explosion that forces the piston downward. This powerful, downward motion is repeated in each cylinder, turning the crankshaft and generating rotational, mechanical energy.

This mechanical energy is then transferred to the alternator, the component responsible for converting it into electricity. The alternator consists of a stationary part, the stator, and a rotating part, the rotor. The rotor, which is connected to the engine's crankshaft, is made up of a series of magnets. As the rotor spins rapidly, its magnetic field cuts through the coils of copper wire in the stator. According to the principles of electromagnetic induction, this movement of a magnetic field through a conductor induces an electrical current. The alternating current (AC) produced is then conditioned and regulated by the control panel before it is sent out as usable power.

Key components work together to ensure this process is efficient and safe:

-

Engine: The prime mover of the generator, responsible for converting fuel into mechanical energy. Its size and efficiency are measured in horsepower or kW.

-

Alternator (Generator End): This is the part that produces the electricity. The rating of the alternator is often expressed in kVA (kilovolt-amperes), which is the apparent power the generator can produce.

-

Fuel System: This system includes the fuel tank, fuel pump, filters, and injectors. It is designed to store and deliver a clean supply of diesel fuel to the engine. The size of the fuel tank directly impacts how long the generator can run without refueling.

-

Cooling System: Generators produce a significant amount of heat. A cooling system, typically using a radiator and fan, prevents the engine from overheating, which is critical for long-term operation.

-

Lubrication System: An oil pump circulates oil throughout the engine to reduce friction and wear between moving parts, helping to extend the lifespan of the generator.

-

Control Panel: This is the brain of the machine. It provides an interface for monitoring the generator's output (kW/kVA), voltage, frequency, and operating hours. It also includes safety features like automatic shutdowns for low oil pressure or high engine temperature.

-

Frame/Housing: The frame provides a solid foundation for the engine and alternator, while the housing (often a sound-attenuated enclosure) protects the components from the elements and significantly reduces noise levels.

The seamless operation of these components allows a diesel generator to provide a stable and reliable source of power, converting the chemical energy in diesel fuel into the electrical energy that powers homes, businesses, and essential infrastructure.

Factors to Consider When Choosing a Diesel Generator

Selecting the right diesel generator is a critical decision that can impact your operations, budget, and peace of mind. To make an informed choice, you must evaluate several key factors beyond just the initial price.

1. Power Requirements (kW/kVA): This is arguably the most important factor. You need to determine the total electrical load you intend to power. Start by listing all the appliances, equipment, and lights you want to run simultaneously. Find the starting wattage (surge power) and running wattage for each item. The starting wattage, which is needed to get motors running, is often much higher than the running wattage. Your generator's output must be able to handle this initial surge. kW (kilowatts) measures the real power, while kVA (kilovolt-amperes) measures the apparent power. For a purely resistive load (like a light bulb), kW and kVA are the same. For motor-driven loads, the kVA rating will be higher than the kW rating. A common rule of thumb is to choose a generator with an output 25-30% higher than your calculated total load to account for future needs and to prevent overloading the unit.

2. Prime vs. Standby Power: It’s crucial to understand the difference between prime power and standby power ratings.

-

Standby Power: This rating is for applications where the generator is used as a backup power source during an emergency outage. It's not intended for continuous use.

-

Prime Power: This rating is for applications where the generator is the primary power source, running for extended periods, such as on a construction site or in a remote location. A generator rated for prime power is built with more robust components and is designed for continuous operation. Always choose a prime power unit if you intend to use it as a consistent power source.

3. Fuel Efficiency and Tank Size: The cost of diesel generator fuel consumption can add up quickly. Look for generators with advanced engines that offer better fuel efficiency. The size of the fuel tank is also a significant consideration. A larger tank means a longer run time without the need for refueling, which is especially important for extended power outages or in remote locations.

4. Noise Level and Emissions: Diesel generators are known for being louder than their gasoline counterparts. Noise levels are measured in decibels (dB). If the generator will be located near a residential area or office building, a unit with a sound-attenuated enclosure is essential. Emissions regulations, such as those from the EPA, are also a factor. Industrial and commercial generators must meet strict environmental standards, so ensure the model you choose is compliant.

5. Automatic Transfer Switch (ATS) Capabilities: For standby power applications, an automatic transfer switch (ATS) is a must-have. An ATS is a smart device that monitors the utility power. When it detects an outage, it automatically switches the electrical load from the utility line to the generator within seconds. When the power is restored, it seamlessly switches the load back and shuts the generator down. This ensures uninterrupted power and eliminates the need for manual operation, which is critical for homes and businesses.

6. Maintenance Requirements and Costs: Like any complex machine, diesel generators require regular maintenance. Consider the cost and availability of replacement parts, filters, and oil. Routine tasks like oil changes, filter replacements, and regular inspections are vital for extending the generator's lifespan. Understanding the long-term diesel generator maintenance costs will help you budget effectively.

Applications of Diesel Generators

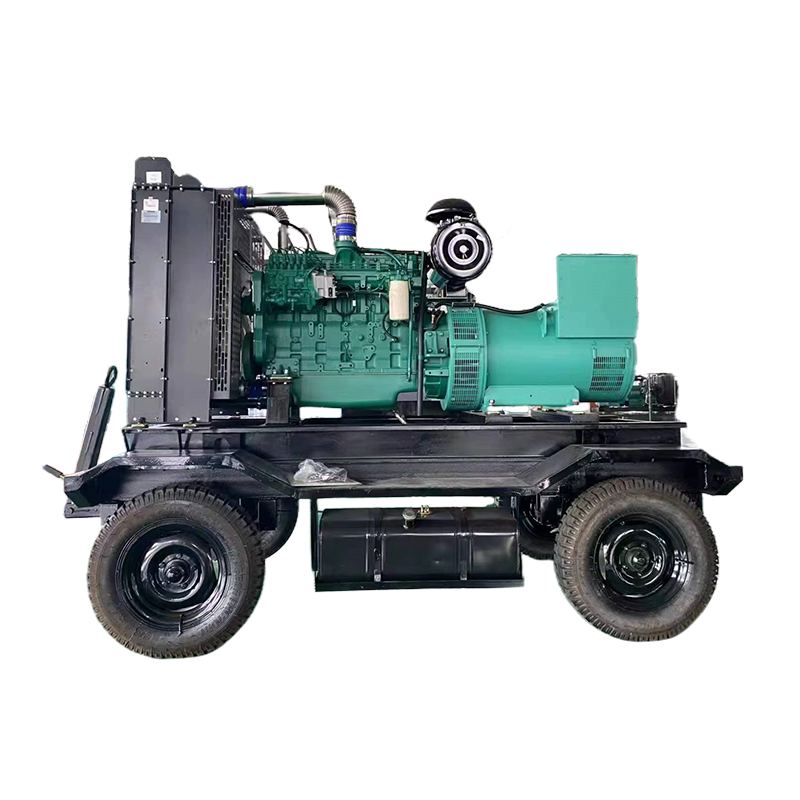

The reliability and versatility of diesel generators have made them indispensable across a wide spectrum of industries and for a variety of critical applications. Their ability to provide consistent, high-output power in diverse environments makes them a go-to solution for both backup and prime power needs.

Residential: Backup Power During Outages

For homeowners, a diesel generator is the ultimate insurance against power outages. Whether caused by severe weather, utility grid failures, or unforeseen accidents, losing power can disrupt daily life, compromise food safety, and even pose a risk to essential medical equipment. A residential standby power generator with an ATS can automatically restore power within seconds, keeping lights on, refrigerators running, and security systems active. Portable diesel generators also serve a valuable purpose for homeowners, providing temporary power for specific appliances or tools during smaller disruptions.

Commercial: Powering Businesses, Offices, and Retail Spaces

In the commercial sector, a power outage is more than an inconvenience; it can result in significant financial losses. Businesses, offices, and retail stores rely on continuous electricity for point-of-sale systems, computers, lighting, and climate control. A standby diesel generator ensures that business operations can continue uninterrupted, protecting against lost sales, data corruption, and operational downtime. This is particularly crucial for businesses with perishable goods or those that operate 24/7.

Industrial: Powering Factories, Construction Sites, and Data Centers

The industrial sector is one of the heaviest users of diesel generators. In factories and manufacturing plants, generators provide a steady and powerful source of electricity to run heavy machinery, assembly lines, and robotic systems. On construction sites, where grid power may not be available, portable and industrial generators serve as the primary power source for welders, saws, and other essential equipment. Data centers, which house mission-critical servers and data storage, use large-scale industrial generators to ensure that servers remain online, preventing data loss and service disruptions that could cost millions. The kVA and kW ratings of these units are often in the thousands, reflecting the immense power requirements of these facilities.

Healthcare: Ensuring Uninterrupted Power for Hospitals and Clinics

In healthcare, a power outage can be a matter of life and death. Hospitals, clinics, and laboratories rely on an uninterruptible power supply to operate life-support systems, surgical equipment, diagnostic machines, and critical patient monitoring devices. Industrial diesel generators are a mandatory part of a hospital's infrastructure, serving as a reliable standby power source that kicks in instantly in the event of a grid failure. Regular maintenance and testing of these units are non-negotiable to ensure they function flawlessly when needed most.

Telecommunications: Maintaining Network Uptime

Telecommunications infrastructure, including cell towers, data switches, and communication hubs, must remain operational at all times to ensure a stable network. A power outage can lead to a complete loss of service for millions of users. Diesel generators are strategically placed at cell tower sites and communication centers to provide continuous power, maintaining network uptime and ensuring that people can make calls, access the internet, and stay connected, especially during emergencies.

Installation and Safety

Proper installation and a strong focus on safety are paramount when dealing with a diesel generator. A well-planned setup not only ensures the generator operates efficiently but also protects people and property from potential hazards.

Proper Placement and Ventilation

The location of your generator is a critical first step. It must be placed on a level, stable surface, typically a concrete pad, to prevent vibration and ensure the unit remains secure. The placement should also be away from windows, doors, and air intakes of your home or building to prevent deadly carbon monoxide from entering the premises. Generators need a significant amount of fresh air for combustion and cooling. Restricting airflow can cause the engine to overheat and fail. A minimum clearance of 3-5 feet on all sides is recommended to allow for proper ventilation and access for maintenance. Additionally, the exhaust pipe must be properly directed away from any structures and high-traffic areas.

Connecting to Electrical Systems (Transfer Switches)

For standby generators, the electrical connection must be handled by a licensed electrician. This involves wiring the generator to an automatic transfer switch (ATS). The ATS is the key component that makes the system safe and effective. It ensures that the generator and the utility grid are never connected at the same time, preventing a dangerous condition known as "backfeeding." Backfeeding sends electricity from the generator back down the utility lines, which can electrocute utility workers who are trying to repair the grid. The ATS also simplifies the process for the user, as it automatically starts the generator during an outage and switches the power source without any manual intervention. For portable generators, a manual transfer switch can be used. This involves plugging the generator into a power inlet box, which is wired to the main electrical panel, and manually flipping a switch to isolate the house from the grid.

Safety Precautions When Handling Fuel

Diesel fuel is less volatile than gasoline, but it is still flammable and must be handled with care. Always store fuel in approved containers and in a well-ventilated area away from living spaces and heat sources. When refueling the generator, always turn off the engine and allow it to cool down completely to prevent any spills from igniting on a hot surface. Avoid smoking near the generator or fuel containers. Spilled fuel should be cleaned up immediately. Regular inspection of the fuel system for leaks is also a crucial part of diesel generator maintenance.

Carbon Monoxide Dangers and Prevention

The most significant safety risk associated with running a diesel generator is carbon monoxide (CO) poisoning. Carbon monoxide is a colorless, odorless, and tasteless gas produced by the combustion engine. Inhaling it can be fatal. To prevent CO poisoning:

-

Never run a generator indoors, in a garage, in a basement, or in any enclosed space.

-

Place the generator at a safe distance from your home or business, ensuring the exhaust is directed away from all windows, doors, and vents.

-

Install carbon monoxide alarms inside your home or business on every level and near sleeping areas. Test them regularly to ensure they are working properly.

Adhering to these safety guidelines for placement, electrical connections, and fuel handling is essential for the safe and reliable operation of your diesel generator, protecting both the equipment and the people around it.

Maintenance and Troubleshooting

A diesel generator is a robust machine, but like any piece of complex equipment, it requires regular maintenance to ensure longevity and reliable performance. Neglecting routine care can lead to costly repairs and, more importantly, a failure to start when you need it most.

Regular Maintenance Tasks

A consistent diesel generator maintenance schedule is the best way to prevent issues and extend the lifespan of your unit.

-

Oil Changes: The engine oil lubricates moving parts and reduces friction. Over time, the oil becomes contaminated with dirt and metal particles. You should change the oil and oil filter after the first 20-30 hours of operation for a new generator, and then typically every 200-250 hours or as recommended by the manufacturer. Using the correct type of oil is crucial for the engine's health.

-

Filter Replacements: There are three primary filters to maintain: the oil filter, the air filter, and the fuel filter. A clogged air filter restricts airflow to the engine, reducing efficiency and power output. A dirty fuel filter can lead to a lack of power or engine stalling. Replace these filters at the recommended intervals.

-

Cooling System Check: The radiator and coolant levels should be checked regularly. Low coolant levels can cause the engine to overheat, leading to serious damage. Inspect hoses for cracks or leaks and ensure the radiator fins are clean and free of debris.

-

Battery Inspection: The battery is responsible for starting the generator. Check the battery terminals for corrosion and ensure the connections are clean and tight. For standby generators, the battery is on a trickle charger, but it should still be checked periodically to ensure it is holding a charge.

-

Exercising the Generator: A diesel generator should be run under a load for a short period once a month. This "exercising" helps to lubricate the seals, prevent moisture buildup in the alternator, and burn off excess fuel deposits. An ATS with an automatic exercise feature can handle this for you.

Common Issues and Troubleshooting Tips

Even with regular maintenance, issues can arise. Knowing some basic diesel generator troubleshooting can help you resolve minor problems quickly.

-

Generator Won't Start: This is one of the most common issues. Start by checking the basics: Is there enough fuel? Is the battery charged and are the terminals clean? Is the circuit breaker in the correct position? If these are all fine, the issue could be a clogged fuel filter or a faulty starter.

-

Loss of Power Output: If the generator is running but not producing enough electricity, check the output voltage on the control panel. The problem could be an overloaded circuit, a tripped breaker, or an issue with the alternator. Ensure your total power load (kW/kVA) is within the generator's capacity.

-

Unusual Noises or Vibrations: Any new noises or excessive vibration are a red flag. These could indicate a loose component, a worn-out belt, or a serious internal engine problem. Shut down the generator immediately and have it inspected.

-

Excessive Smoke: The color of the exhaust smoke can tell you a lot about the engine's health. Blue smoke indicates that oil is burning, black smoke can mean a clogged air filter or a rich fuel-to-air mixture, and white smoke could point to an injector issue or a cooling problem.

Extending the Lifespan of Your Diesel Generator

Beyond routine maintenance, you can extend your generator's life by not overloading it, keeping it clean, and ensuring it is stored in a dry, protected environment. Using high-quality fuel and following all manufacturer recommendations will ensure your investment provides reliable power for years to come.

Environmental Considerations

While diesel generators are a powerful and reliable source of electricity, their operation has an environmental impact that must be acknowledged and managed. Modern technology and stricter regulations have made significant strides in reducing this impact.

Emissions Standards and Regulations

The primary environmental concern with diesel generators is the exhaust emissions they produce. The combustion of diesel fuel releases various pollutants, including nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM), often seen as black smoke. These pollutants contribute to air pollution and can have negative health effects.

In response to these concerns, governments and environmental agencies worldwide have implemented strict emissions standards for diesel engines. In the United States, for example, the Environmental Protection Agency (EPA) has set different tiers of standards (Tier 1, Tier 2, etc., up to the current Tier 4 Final) that all new generators must meet. These regulations have driven significant advancements in engine technology, leading to cleaner-burning, more fuel-efficient models. Compliance with these standards is a key factor in the design and operation of new generators, particularly for large industrial generators.

Reducing Environmental Impact

Beyond regulatory compliance, several practices can help reduce the environmental footprint of your diesel generator:

-

Fuel Efficiency: Modern diesel engines are engineered for greater fuel efficiency. This not only lowers operational costs but also means less fuel is consumed to generate the same amount of electricity, resulting in fewer emissions. Regular maintenance, such as replacing air and fuel filters, is crucial for maintaining this efficiency.

-

Alternative Fuels: Some generators can be modified to run on alternative fuels or a blend of fuels. Biodiesel, a renewable fuel made from vegetable oils or animal fats, can be used in many diesel engines with little to no modification. Using biodiesel can significantly reduce carbon emissions. However, it's important to check the generator's specifications to ensure compatibility and to consider potential maintenance differences.

-

Regular Maintenance: A well-maintained generator is a cleaner-running generator. Clogged filters, old oil, and worn-out injectors can all lead to incomplete combustion and higher emissions. Following a strict diesel generator maintenance schedule ensures the engine runs as cleanly and efficiently as possible.

-

Proper Disposal of Waste Oil and Filters: The responsible disposal of waste products is as important as managing emissions. Used oil from oil changes and old filters are considered hazardous waste and should never be poured down a drain or thrown in the trash. These materials must be taken to a designated recycling center or a service that handles hazardous waste. Many auto parts stores and recycling centers accept used oil for free.

By adhering to emissions standards, choosing more efficient models, and practicing responsible maintenance and waste disposal, users of diesel generators can minimize their environmental impact. The balance between the need for reliable power and environmental stewardship is a key consideration in the ongoing evolution of generator technology.

Future Trends in Diesel Generator Technology

The world of power generation is constantly evolving, driven by the need for greater efficiency, reduced environmental impact, and smarter, more integrated systems. The diesel generator, a workhorse of the industry, is at the forefront of this innovation, with several key trends shaping its future.

Advancements in Engine Design and Efficiency

Manufacturers are continually refining diesel engine technology to squeeze more electricity out of every drop of fuel. This includes improvements in fuel injection systems, which atomize fuel more precisely for cleaner, more complete combustion. Turbocharging and electronic engine controls are becoming standard, optimizing the air-to-fuel ratio and performance under varying loads. These advancements not only reduce diesel generator fuel consumption and operational costs but also help meet increasingly stringent emissions regulations. The focus is on creating engines that are smaller, lighter, and more powerful for their size, making generators more compact and efficient.

Hybrid Diesel Generators with Renewable Energy Integration

One of the most significant trends is the move towards hybrid power systems. These systems combine a diesel generator with renewable energy sources, such as solar panels and battery storage. The generator can operate for fewer hours, primarily to charge the batteries or to handle peak loads, while the renewable source provides continuous, clean power during the day. This "genset-hybrid" model offers the best of both worlds: the reliability and high-power output of a diesel generator and the long-term cost savings and low emissions of renewable energy. This is particularly beneficial for off-grid applications or for facilities that need a reliable, cost-effective backup solution.

Smart Generator Monitoring and Control Systems

The rise of the Internet of Things (IoT) is bringing a new level of intelligence to diesel generators. Modern generators are now being equipped with smart monitoring and control systems. These systems allow operators to remotely monitor the generator's performance in real-time from a smartphone or computer. They can track key metrics such as kW/kVA output, fuel levels, oil pressure, engine temperature, and run hours.

These smart systems can also alert technicians to potential issues before they become major problems, enabling proactive maintenance and reducing downtime. For example, the system can send an alert when a filter needs to be replaced or when the fuel level is getting low. This predictive maintenance capability, along with the ability to remotely start or stop the unit, is a game-changer for large-scale operations and for managing a fleet of generators across multiple locations. Some systems even integrate with an automatic transfer switch (ATS) to provide comprehensive power management for a site.

These future trends are moving diesel generators beyond simple mechanical devices and transforming them into integrated, intelligent components of a larger, more sustainable energy ecosystem. The focus on efficiency, integration with renewables, and smart technology ensures that the diesel generator will continue to be a relevant and essential tool for powering our lives and businesses for years to come.

English

English Español

Español عربى

عربى